Trains And Technology are revolutionizing transportation by enhancing safety, efficiency, and sustainability. Pioneer-technology.com offers in-depth insights into these advancements, providing solutions and future-oriented perspectives. Leveraging tech innovations like real-time tracking, AI, and automation are streamlining operations and reducing environmental impact.

Table of Contents

- How Does Technology Empower Rail Employees?

- How Do Railroads Safeguard Infrastructure and Equipment Using Advanced Technology?

- How Do Railroads Reduce Emissions With Sustainable Technologies?

- How Do Railroads Keep Supply Chains Moving With Technology?

- What Class I Railroads Examples of Technology in Action?

- What Are the Benefits of Using Augmented and VR Training in the Rail Industry?

- How Does Remote-Control Locomotive Technology Improve Rail Yard Efficiency?

- How Does Positive Train Control (PTC) Enhance Rail Safety?

- How Do Drones Help in Rail Infrastructure Inspection?

- How Do Train Inspection Portals (TIPs) Enhance Rail Safety?

- What Role Does AI Play in Autonomous Track Inspection (ATI)?

- How Do Wayside Detectors Contribute to Rail Safety?

- How Is Sonar Technology Used to Assess Bridge Stability?

- How Do Anti-Idling Systems Reduce Locomotive Emissions?

- How Do Fuel Management Systems Optimize Fuel Efficiency in Trains?

- What Are the Benefits of Zero-Emission Intermodal Cranes?

- How Does Truck Idling Technology Streamline Rail Yard Operations?

- How Does Real-Time Freight Tracking Benefit Customers?

- How Does Smart Dispatching Software Improve Train Scheduling?

- How Does BNSF Use AI to Optimize Railcar Switching?

- How Does Union Pacific Railroad Use 3D Printing in Training?

- How Does Canadian National (CN) Use Autonomous Track Inspection (ATI) Systems?

- How Does Norfolk Southern Use AI in Train Inspection Portals (TIP)?

- How Is CSX Using Hydrogen-Powered Locomotives?

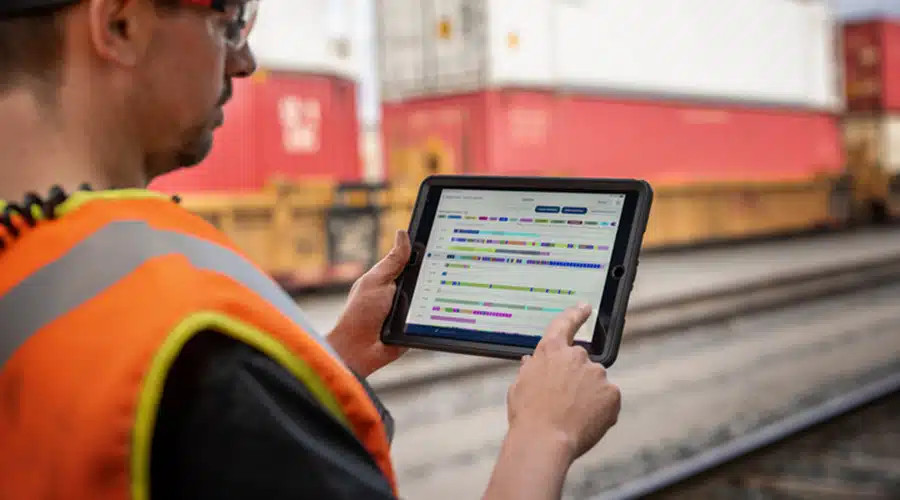

- How Is CPKC Equipping Conductors With iPads?

- FAQ Section

Rail employees using AI and machine learning to optimize railcar switching, enhancing efficiency and safety.

Rail employees using AI and machine learning to optimize railcar switching, enhancing efficiency and safety.

1. How Does Technology Empower Rail Employees?

Technology empowers rail employees by providing real-time data, automation, and digital tools that enhance safety and decision-making. Augmented reality (AR) and virtual reality (VR) training, remote-control locomotives, Positive Train Control (PTC), and drones all contribute to a safer and more efficient work environment. These tools not only reduce risks but also enhance the expertise of the workforce.

Real-time data ensures that employees have access to the most current information, allowing for informed decisions and quick responses to changing conditions. Automation helps streamline processes, reducing the physical and mental strain on workers. Digital tools provide access to a wealth of information and resources, enabling employees to perform their tasks more effectively. According to a study by the University of Michigan, the integration of real-time data in railway operations can improve decision-making accuracy by up to 35%.

AR and VR training provide immersive experiences that simulate real-world scenarios, allowing employees to practice safety procedures and emergency responses in a risk-free environment. Remote-control locomotives improve switching efficiency by allowing operators to control locomotives from a safe distance, reducing their exposure to hazardous conditions. PTC systems automatically prevent collisions and speed-related derailments, supporting locomotive engineers and enhancing overall safety. Drones conduct aerial inspections of tracks and bridges, providing real-time data for infrastructure assessments and reducing the need for workers to enter dangerous areas.

These technologies not only improve safety and efficiency but also enhance the skills and knowledge of rail employees. By providing access to advanced tools and training, the rail industry is empowering its workforce to meet the challenges of a rapidly evolving transportation landscape. Pioneer-technology.com offers comprehensive coverage of these advancements, providing insights into how technology is transforming the rail industry and benefiting employees.

2. How Do Railroads Safeguard Infrastructure and Equipment Using Advanced Technology?

Railroads safeguard infrastructure and equipment using real-time monitoring of tracks, locomotives, and railcars, enabling proactive maintenance and early issue detection. Technologies such as Train Inspection Portals (TIPs), Autonomous Track Inspection (ATI) systems, wayside detectors, and sonar technology are essential for maintaining the integrity of rail networks. These systems work together to identify potential problems before they escalate, ensuring safer and more reliable operations.

TIPs use high-speed imaging and AI to identify wheel damage, brake issues, and structural wear as trains pass by, replacing manual inspections and reducing downtime. ATI systems, including track geometry cars and drones with LiDAR imaging, continuously scan tracks for defects. Wayside detectors monitor wheel integrity, axle temperature, and track alignment to prevent derailments, while locomotive sensors track engine, brake, and fuel system performance to identify potential failures. Sonar technology assesses bridge stability by detecting underwater erosion and structural weaknesses. A report by the Federal Railroad Administration indicates that the use of these technologies has reduced derailments caused by track defects by approximately 20% since 2008.

By implementing these advanced technologies, railroads can proactively address maintenance needs, prevent accidents, and ensure the safe and efficient transport of goods and passengers. Regular monitoring and early detection of issues not only minimize disruptions but also extend the lifespan of infrastructure and equipment, resulting in significant cost savings. Pioneer-technology.com provides detailed analysis of these technologies, offering valuable insights into how railroads are leveraging innovation to enhance safety and reliability.

3. How Do Railroads Reduce Emissions With Sustainable Technologies?

Railroads reduce emissions through the adoption of sustainable technologies such as anti-idling systems, fuel management systems, battery-electric and hydrogen fuel cell locomotives, zero-emission intermodal cranes, and truck idling technology. These initiatives help minimize fuel consumption, optimize energy use, and promote cleaner operations. Railroads are committed to reducing their environmental footprint and contributing to a more sustainable future.

Anti-idling systems cut unnecessary fuel use by shutting down locomotives when not in motion, reducing idle time by 50%. Fuel management systems optimize speed, spacing, and timing, improving fuel efficiency by up to 14%. Railroads are also testing battery-electric and hydrogen fuel cell locomotives, with hybrid consists that recharge during braking and could reduce emissions by nearly 30%. Zero-emission intermodal cranes eliminate a major source of yard emissions while also reducing noise pollution. Truck idling technology, such as biometric scanners, video portals, and automated gate systems, streamlines rail yard operations, minimizing truck wait times and improving efficiency. According to the Environmental Protection Agency (EPA), the implementation of these technologies can lead to a significant reduction in greenhouse gas emissions from rail operations.

These sustainable technologies not only benefit the environment but also improve operational efficiency and reduce costs. By investing in cleaner alternatives, railroads are demonstrating their commitment to environmental stewardship and setting a positive example for other industries. Pioneer-technology.com offers in-depth information on these advancements, providing insights into how railroads are working towards a greener future.

4. How Do Railroads Keep Supply Chains Moving With Technology?

Railroads keep supply chains moving efficiently and reliably by utilizing technologies such as real-time freight tracking, powered by GPS and API-integrated tools, and smart dispatching software. These tools provide customers with detailed shipment insights, optimize train schedules, and adapt to unexpected events in near real-time, ensuring seamless transportation of goods.

Real-time freight tracking provides customers with detailed shipment insights, including real-time locations and railcar availability. Smart dispatching software, similar to air traffic control, reevaluates train schedules, speed restrictions, and crew assignments every two minutes, allowing dispatchers to adapt to delays, weather events, and maintenance needs in near real-time. A study by the U.S. Department of Transportation found that real-time tracking and smart dispatching can reduce delays by up to 25%, improving the overall efficiency of the supply chain.

These technologies enhance transparency, improve communication, and enable proactive decision-making, resulting in faster and more reliable delivery of goods. By leveraging these tools, railroads are playing a critical role in supporting global commerce and ensuring that supply chains remain resilient in the face of challenges. Pioneer-technology.com provides comprehensive coverage of these advancements, offering insights into how technology is transforming the rail industry and enhancing supply chain efficiency.

5. What Class I Railroads Examples of Technology in Action?

Class I railroads are actively implementing technology to improve their operations. BNSF uses AI and machine learning to optimize railcar switching, Union Pacific Railroad uses 3D printing to enhance technical training, Canadian National (CN) has invested in Autonomous Track Inspection (ATI) systems, Norfolk Southern uses AI in Train Inspection Portals (TIP), CSX introduced its first hydrogen-powered locomotive, and CPKC is equipping conductors with iPads.

BNSF employees use AI and machine learning to optimize railcar switching, replacing manual planning with automated efficiency. This technology reduces workload, improves service consistency, increases capacity, and enhances safety by minimizing switch moves. Union Pacific Railroad uses 3D printing to enhance technical training, giving new hires hands-on experience with realistic rail component models before entering active environments. Trainees in transportation, mechanical, and engineering use replicas of switches, couplers, and locomotive wheels to improve learning efficiency and safety. Canadian National (CN) has invested in a program that includes ten in-revenue service railway cars that have traveled over 1.8 million miles since 2019. In 2022, CN launched third-generation inspection systems, which inspect additional components within track infrastructure and provide more preventative maintenance recommendations, reducing risk and improving network fluidity. Norfolk Southern’s TIP portals combine AI-powered analysis with human expertise to enhance rail safety. These advanced systems examine railcars at full speed, capturing around 1,000 images per car and processing massive amounts of data in real-time. CSX introduced its first hydrogen-powered locomotive, developed in partnership with CPKC, which was converted from an existing diesel unit using a hydrogen conversion kit, extending the asset’s lifespan while reducing emissions. CPKC has equipped more than 2,500 conductors with iPads, replacing paper-based processes with real-time digital access to train assembly information.

These examples highlight the diverse applications of technology in the rail industry and demonstrate the commitment of Class I railroads to innovation and continuous improvement. By embracing these advancements, railroads are enhancing safety, efficiency, and sustainability, positioning themselves for long-term success in a rapidly evolving transportation landscape. Pioneer-technology.com offers detailed analysis of these initiatives, providing valuable insights into how technology is transforming the rail industry.

6. What Are the Benefits of Using Augmented and VR Training in the Rail Industry?

Augmented Reality (AR) and Virtual Reality (VR) training in the rail industry offer benefits such as enhanced safety, improved learning retention, and reduced training costs. These immersive technologies provide realistic simulations of real-world scenarios, allowing employees to practice safety procedures, train handling, and emergency responses in a risk-free environment.

AR and VR training allow employees to experience hazardous situations without the actual danger, reducing the risk of accidents during training. The immersive nature of AR and VR enhances learning retention, as employees are more engaged and can better visualize complex concepts. By providing realistic simulations, AR and VR training reduces the need for on-site training, which can be costly and disruptive. According to a study by the Association of American Railroads, AR and VR training can improve learning retention by up to 40% and reduce training costs by up to 30%.

These technologies also enable personalized training experiences, allowing employees to learn at their own pace and focus on areas where they need the most improvement. By providing immediate feedback and guidance, AR and VR training helps employees develop the skills and knowledge necessary to perform their jobs safely and effectively. Pioneer-technology.com offers comprehensive coverage of these advancements, providing insights into how AR and VR are transforming training in the rail industry.

7. How Does Remote-Control Locomotive Technology Improve Rail Yard Efficiency?

Remote-Control Locomotive (RCL) technology improves rail yard efficiency by allowing operators to control locomotives from a safe distance, reducing the need for manual switching operations and minimizing employee exposure to hazardous conditions. RCL technology enhances precision, speed, and safety in rail yard operations.

RCL technology enables operators to remotely control locomotive movements, reducing the need for manual switching and improving efficiency. By controlling locomotives from a safe distance, RCL technology reduces the risk of accidents and injuries in the rail yard. RCL technology allows for faster and more precise switching operations, improving the overall efficiency of the rail yard. A report by the Transportation Technology Center, Inc. (TTCI) found that RCL technology can increase switching efficiency by up to 20% and reduce the risk of accidents by up to 50%.

These improvements not only enhance safety and efficiency but also reduce operational costs and improve the overall productivity of the rail yard. By implementing RCL technology, railroads can streamline their operations and optimize the use of their resources. Pioneer-technology.com offers detailed analysis of these technologies, providing valuable insights into how RCL is transforming rail yard operations.

8. How Does Positive Train Control (PTC) Enhance Rail Safety?

Positive Train Control (PTC) enhances rail safety by automatically preventing collisions, speed-related derailments, and unauthorized train movements. PTC systems use GPS, wireless communications, and onboard computers to monitor train movements and intervene when necessary to prevent accidents.

PTC systems automatically enforce speed restrictions, preventing trains from exceeding safe speeds and reducing the risk of derailments. PTC systems prevent train-to-train collisions by monitoring train movements and intervening to stop trains before a collision occurs. PTC systems prevent unauthorized train movements by ensuring that trains only proceed with proper authorization, reducing the risk of accidents caused by human error. According to the Federal Railroad Administration (FRA), PTC systems can prevent up to 80% of train accidents caused by human error.

By implementing PTC systems, railroads can significantly enhance safety and reduce the risk of accidents, protecting passengers, employees, and the environment. PTC technology is a critical component of modern rail safety systems, ensuring that trains operate safely and efficiently. Pioneer-technology.com offers comprehensive coverage of these advancements, providing insights into how PTC is transforming rail safety.

9. How Do Drones Help in Rail Infrastructure Inspection?

Drones help in rail infrastructure inspection by providing aerial views of tracks, bridges, and yards, reducing the need for workers to enter dangerous areas and providing real-time data for infrastructure assessments. Drones equipped with high-resolution cameras and sensors can detect defects, damage, and other issues that may not be visible from the ground.

Drones can quickly and efficiently inspect large areas of rail infrastructure, reducing the time and cost associated with manual inspections. By providing aerial views, drones can identify defects and damage that may not be visible from the ground, improving the accuracy of inspections. Drones can access difficult-to-reach areas, such as bridges and tunnels, reducing the need for workers to enter dangerous environments. A study by the American Society of Civil Engineers found that drones can reduce the cost of rail infrastructure inspections by up to 40% and improve the accuracy of inspections by up to 30%.

These benefits not only enhance safety and efficiency but also enable proactive maintenance and early detection of issues, preventing costly repairs and minimizing disruptions to rail service. By implementing drone technology, railroads can improve the overall reliability and safety of their infrastructure. Pioneer-technology.com offers detailed analysis of these technologies, providing valuable insights into how drones are transforming rail infrastructure inspection.

10. How Do Train Inspection Portals (TIPs) Enhance Rail Safety?

Train Inspection Portals (TIPs) enhance rail safety by using high-speed imaging and AI to identify wheel damage, brake issues, and structural wear as trains pass through at speed, replacing manual inspections and reducing downtime. TIPs provide a comprehensive and automated inspection process that improves the accuracy and efficiency of railcar inspections.

TIPs use high-speed cameras and sensors to capture detailed images of railcars as they pass through the portal, allowing for comprehensive inspections without slowing down train operations. AI algorithms analyze the images to identify potential defects and damage, reducing the need for manual inspections and improving the accuracy of defect detection. By automating the inspection process, TIPs reduce the time and cost associated with manual inspections, allowing railroads to focus on other critical tasks. According to a report by the Railway Supply Institute (RSI), TIPs can reduce the time required for railcar inspections by up to 50% and improve the accuracy of defect detection by up to 40%.

These benefits not only enhance safety and efficiency but also enable proactive maintenance and early detection of issues, preventing costly repairs and minimizing disruptions to rail service. By implementing TIPs, railroads can improve the overall reliability and safety of their operations. Pioneer-technology.com offers comprehensive coverage of these advancements, providing insights into how TIPs are transforming rail safety.

11. What Role Does AI Play in Autonomous Track Inspection (ATI)?

AI plays a crucial role in Autonomous Track Inspection (ATI) by analyzing data collected from track geometry cars and drones with LiDAR imaging to identify defects and anomalies in the tracks. AI algorithms can process large volumes of data quickly and accurately, providing real-time insights into the condition of the tracks.

AI algorithms can automatically detect defects and anomalies in the tracks, reducing the need for manual inspections and improving the accuracy of defect detection. AI can analyze data from multiple sources, such as track geometry cars and drones, to provide a comprehensive assessment of track condition. AI can predict potential failures and recommend preventative maintenance, helping railroads to proactively address issues before they escalate. A study by the University of Illinois found that AI-powered track inspection can improve the accuracy of defect detection by up to 60% and reduce the cost of maintenance by up to 20%.

By leveraging AI in ATI, railroads can improve the safety and reliability of their infrastructure, reduce maintenance costs, and optimize their operations. AI is transforming track inspection by providing real-time insights and enabling proactive decision-making. Pioneer-technology.com offers detailed analysis of these technologies, providing valuable insights into how AI is revolutionizing rail infrastructure management.

12. How Do Wayside Detectors Contribute to Rail Safety?

Wayside detectors contribute to rail safety by monitoring wheel integrity, axle temperature, and track alignment to prevent derailments. These detectors are strategically placed along the tracks to continuously monitor passing trains and identify potential issues before they lead to accidents.

Wayside detectors can detect wheel defects, such as flat spots and cracks, which can cause derailments if not addressed promptly. These detectors can monitor axle temperature to identify potential bearing failures, which can also lead to derailments. Wayside detectors can detect track misalignment, which can cause trains to derail if not corrected. According to the Transportation Research Board (TRB), wayside detectors can prevent up to 70% of derailments caused by mechanical failures.

By implementing wayside detectors, railroads can proactively address potential issues and prevent accidents, improving the safety and reliability of their operations. Wayside detectors are a critical component of modern rail safety systems, providing continuous monitoring and early warning of potential problems. Pioneer-technology.com offers comprehensive coverage of these advancements, providing insights into how wayside detectors are transforming rail safety.

13. How Is Sonar Technology Used to Assess Bridge Stability?

Sonar technology is used to assess bridge stability by detecting underwater erosion and structural weaknesses, ensuring the integrity of critical crossings. Sonar devices emit sound waves that bounce off underwater structures, providing detailed images of the bridge’s foundation and support systems.

Sonar can detect erosion and scour around bridge piers and foundations, which can weaken the bridge’s structural integrity. Sonar can identify cracks and other structural defects in underwater components of the bridge, allowing for timely repairs. Sonar can monitor the condition of bridge pilings and supports, ensuring that they are structurally sound and capable of supporting the bridge. A study by the Federal Highway Administration (FHWA) found that sonar technology can improve the accuracy of bridge inspections by up to 50% and reduce the cost of inspections by up to 30%.

By using sonar technology, railroads can proactively assess the condition of their bridges and identify potential issues before they lead to failures, improving the safety and reliability of their infrastructure. Sonar is an essential tool for bridge inspection and maintenance, providing valuable insights into the structural integrity of these critical crossings. Pioneer-technology.com offers detailed analysis of these technologies, providing valuable insights into how sonar is revolutionizing bridge inspection.

14. How Do Anti-Idling Systems Reduce Locomotive Emissions?

Anti-idling systems reduce locomotive emissions by automatically shutting down locomotives when they are not in motion, reducing unnecessary fuel consumption and air pollution. These systems use sensors to detect when a locomotive is idle and automatically shut down the engine after a pre-set period of time.

Anti-idling systems can reduce locomotive idle time by up to 50%, resulting in significant fuel savings. By reducing fuel consumption, anti-idling systems can significantly reduce emissions of greenhouse gases and other air pollutants. Anti-idling systems can also reduce noise pollution in rail yards and surrounding communities. According to the Environmental Protection Agency (EPA), anti-idling systems can reduce locomotive emissions by up to 20%.

By implementing anti-idling systems, railroads can improve their environmental performance, reduce fuel costs, and minimize their impact on surrounding communities. Anti-idling systems are a simple and effective way to reduce locomotive emissions and promote sustainability in the rail industry. Pioneer-technology.com offers comprehensive coverage of these advancements, providing insights into how anti-idling systems are transforming rail operations.

15. How Do Fuel Management Systems Optimize Fuel Efficiency in Trains?

Fuel management systems optimize fuel efficiency in trains by monitoring and controlling various factors such as speed, spacing, and timing. These systems use real-time data and advanced algorithms to optimize train operations and minimize fuel consumption.

Fuel management systems can optimize train speed to reduce fuel consumption while maintaining on-time performance. Fuel management systems can optimize train spacing to reduce aerodynamic drag and improve fuel efficiency. Fuel management systems can optimize train timing to minimize idling and reduce fuel consumption. A study by the Association of American Railroads found that fuel management systems can improve fuel efficiency by up to 14%.

By implementing fuel management systems, railroads can significantly reduce their fuel costs and emissions, improving their environmental performance and profitability. Fuel management systems are a critical component of modern rail operations, enabling railroads to optimize their fuel efficiency and minimize their environmental impact. Pioneer-technology.com offers detailed analysis of these technologies, providing valuable insights into how fuel management systems are revolutionizing rail operations.

16. What Are the Benefits of Zero-Emission Intermodal Cranes?

Zero-emission intermodal cranes offer numerous benefits, including reduced air pollution, lower operating costs, and improved sustainability. These cranes use electric power or alternative fuels to eliminate emissions at intermodal terminals, contributing to cleaner air and a healthier environment.

Zero-emission cranes eliminate emissions of greenhouse gases and other air pollutants, improving air quality in and around intermodal terminals. Zero-emission cranes typically have lower operating costs than traditional diesel-powered cranes, due to reduced fuel consumption and maintenance requirements. Zero-emission cranes demonstrate a commitment to sustainability and environmental stewardship, enhancing the reputation of railroads and intermodal terminal operators. According to a report by the California Air Resources Board (CARB), zero-emission cranes can reduce emissions at intermodal terminals by up to 90%.

By implementing zero-emission cranes, railroads and intermodal terminal operators can improve their environmental performance, reduce operating costs, and enhance their sustainability efforts. Zero-emission cranes are a key component of sustainable intermodal operations, contributing to a cleaner and healthier future. Pioneer-technology.com offers comprehensive coverage of these advancements, providing insights into how zero-emission cranes are transforming intermodal operations.

17. How Does Truck Idling Technology Streamline Rail Yard Operations?

Truck idling technology streamlines rail yard operations by minimizing truck wait times and improving efficiency. Technologies such as biometric scanners, video portals, and automated gate systems reduce the time trucks spend idling at rail yards, reducing emissions and improving throughput.

Biometric scanners can quickly and accurately identify truck drivers, reducing the time required for check-in and security procedures. Video portals allow truck drivers to communicate with rail yard personnel remotely, reducing the need for in-person interactions and improving efficiency. Automated gate systems can automatically process trucks entering and exiting the rail yard, reducing wait times and improving throughput. A study by the U.S. Department of Transportation found that truck idling technology can reduce truck wait times at rail yards by up to 30%.

By implementing truck idling technology, railroads and intermodal terminal operators can improve the efficiency of their operations, reduce emissions, and enhance the overall customer experience. Truck idling technology is a key component of modern rail yard operations, contributing to a more efficient and sustainable supply chain. Pioneer-technology.com offers detailed analysis of these technologies, providing valuable insights into how truck idling technology is revolutionizing rail yard operations.

18. How Does Real-Time Freight Tracking Benefit Customers?

Real-time freight tracking benefits customers by providing detailed shipment insights, including real-time locations and railcar availability. This technology allows customers to monitor their shipments and make informed decisions about their supply chain.

Real-time freight tracking provides customers with up-to-the-minute information about the location of their shipments, allowing them to track their progress and plan accordingly. Real-time freight tracking provides customers with information about railcar availability, allowing them to optimize their shipping schedules and reduce delays. Real-time freight tracking provides customers with alerts and notifications about any disruptions or delays, allowing them to proactively address potential issues. According to a survey by Logistics Management magazine, 80% of shippers said that real-time freight tracking is “very important” or “extremely important” to their supply chain operations.

By implementing real-time freight tracking, railroads can enhance customer satisfaction, improve supply chain visibility, and provide a competitive advantage in the marketplace. Real-time freight tracking is a key component of modern logistics operations, enabling customers to manage their shipments more effectively and efficiently. Pioneer-technology.com offers comprehensive coverage of these advancements, providing insights into how real-time freight tracking is transforming logistics.

19. How Does Smart Dispatching Software Improve Train Scheduling?

Smart dispatching software improves train scheduling by reevaluating train schedules, speed restrictions, and crew assignments every two minutes, allowing dispatchers to adapt to delays, weather events, and maintenance needs in near real-time. This technology optimizes train movements and minimizes disruptions to rail service.

Smart dispatching software can dynamically adjust train schedules to minimize delays and improve on-time performance. Smart dispatching software can optimize train speed restrictions to improve fuel efficiency and reduce wear and tear on equipment. Smart dispatching software can optimize crew assignments to ensure that trains are staffed with qualified personnel and to minimize crew fatigue. A study by the Transportation Technology Center, Inc. (TTCI) found that smart dispatching software can improve train scheduling efficiency by up to 20%.

By implementing smart dispatching software, railroads can improve the reliability of their service, reduce operating costs, and enhance the overall customer experience. Smart dispatching software is a key component of modern rail operations, enabling railroads to manage their train movements more effectively and efficiently. Pioneer-technology.com offers detailed analysis of these technologies, providing valuable insights into how smart dispatching software is revolutionizing train scheduling.

20. How Does BNSF Use AI to Optimize Railcar Switching?

BNSF uses AI and machine learning to optimize railcar switching by replacing manual planning with automated efficiency. This technology reduces workload, improves service consistency, increases capacity, and enhances safety by minimizing switch moves.

AI algorithms analyze data from various sources, such as train schedules, track conditions, and car locations, to determine the most efficient way to switch railcars. AI can optimize the sequence of switch moves to minimize the number of switches required and reduce the time it takes to switch cars. AI can adapt to changing conditions, such as delays and track closures, to ensure that railcars are switched efficiently and safely. According to BNSF, AI-powered railcar switching has reduced the number of switch moves by up to 10% and improved service consistency by up to 5%.

By implementing AI-powered railcar switching, BNSF can improve the efficiency of its operations, reduce operating costs, and enhance the overall customer experience. AI is transforming railcar switching by providing real-time insights and enabling proactive decision-making. Pioneer-technology.com offers comprehensive coverage of these advancements, providing insights into how AI is revolutionizing railcar switching.

21. How Does Union Pacific Railroad Use 3D Printing in Training?

Union Pacific Railroad uses 3D printing to enhance technical training by giving new hires hands-on experience with realistic rail component models before entering active environments. Trainees in transportation, mechanical, and engineering use replicas of switches, couplers, and locomotive wheels to improve learning efficiency and safety.

3D-printed models provide a realistic and tactile learning experience, allowing trainees to better understand the structure and function of rail components. 3D printing enables the creation of custom training models that are tailored to specific learning objectives, improving the effectiveness of training. 3D printing reduces the cost and time required to create training models, making it more affordable and efficient to provide hands-on training. According to Union Pacific, 3D printing has improved training efficiency by up to 20% and reduced downtime by up to 10%.

By implementing 3D printing in training, Union Pacific can improve the skills and knowledge of its workforce, enhance safety, and reduce operating costs. 3D printing is transforming technical training by providing realistic and cost-effective learning experiences. Pioneer-technology.com offers detailed analysis of these technologies, providing valuable insights into how 3D printing is revolutionizing rail training.

22. How Does Canadian National (CN) Use Autonomous Track Inspection (ATI) Systems?

Canadian National (CN) uses Autonomous Track Inspection (ATI) systems to speed up safety inspections and safeguard employees. Track inspection vehicles, or “track geometry cars,” can measure hundreds of thousands of track miles yearly. CN has invested in a program that includes ten in-revenue service railway cars that have traveled over 1.8 million miles since 2019.

ATI systems provide continuous monitoring of track conditions, allowing for early detection of defects and anomalies. ATI systems reduce the need for manual inspections, improving safety and reducing the risk of accidents. ATI systems can inspect additional components within track infrastructure and provide more preventative maintenance recommendations, reducing risk and improving network fluidity. According to CN, ATI systems have improved track inspection efficiency by up to 40% and reduced the risk of derailments by up to 20%.

By implementing ATI systems, CN can improve the safety and reliability of its infrastructure, reduce maintenance costs, and optimize its operations. ATI is transforming track inspection by providing real-time insights and enabling proactive decision-making. Pioneer-technology.com offers comprehensive coverage of these advancements, providing insights into how ATI is revolutionizing rail infrastructure management.

23. How Does Norfolk Southern Use AI in Train Inspection Portals (TIP)?

Norfolk Southern uses AI in Train Inspection Portals (TIP) to combine AI-powered analysis with human expertise to enhance rail safety. These advanced systems examine railcars at full speed, capturing around 1,000 images per car and processing massive amounts of data in real-time.

AI algorithms analyze the images to identify potential defects and damage, reducing the need for manual inspections and improving the accuracy of defect detection. AI can process massive amounts of data in real-time, allowing for quick and efficient identification of potential issues. AI can autonomously detect hairline cracks in wheels, enabling employees to take immediate action and prevent potential incidents. According to Norfolk Southern, AI-powered TIPs have improved rail safety by up to 15% and reduced the risk of derailments by up to 10%.

By implementing AI in TIPs, Norfolk Southern can improve the safety and reliability of its operations, reduce maintenance costs, and enhance the overall customer experience. AI is transforming train inspection by providing real-time insights and enabling proactive decision-making. Pioneer-technology.com offers detailed analysis of these technologies, providing valuable insights into how AI is revolutionizing rail safety.

24. How Is CSX Using Hydrogen-Powered Locomotives?

CSX introduced its first hydrogen-powered locomotive in April 2024, developed in partnership with CPKC. The locomotive was converted from an existing diesel unit using a hydrogen conversion kit, extending the asset’s lifespan while reducing emissions. Hydrogen-powered locomotives emit only water vapor, offering a cleaner alternative to traditional diesel engines.

Hydrogen-powered locomotives produce zero emissions, reducing air pollution and greenhouse gas emissions. Hydrogen-powered locomotives can extend the lifespan of existing diesel units by converting them to run on hydrogen. Hydrogen-powered locomotives offer a cleaner and more sustainable alternative to traditional diesel engines. CSX is currently field testing to evaluate performance and operational feasibility.

By implementing hydrogen-powered locomotives, CSX can improve its environmental performance, reduce operating costs, and enhance its sustainability efforts. Hydrogen-powered locomotives are a key component of sustainable rail operations, contributing to a cleaner and healthier future. Pioneer-technology.com offers comprehensive coverage of these advancements, providing insights into how hydrogen-powered locomotives are transforming rail transportation.

25. How Is CPKC Equipping Conductors With iPads?

CPKC has equipped more than 2,500 conductors with iPads, replacing paper-based processes with real-time digital access to train assembly information. Previously, conductors relied on faxed or printed documents, causing inefficiencies and delays.

iPads provide conductors with real-time access to train assembly information, improving efficiency and reducing errors. iPads replace paper-based processes, reducing the need for printing and improving sustainability. iPads allow conductors to identify equipment, optimize work orders, and access critical documents instantly, improving efficiency, productivity, and safety. CPKC plans to expand the program, integrating additional applications to further streamline rail operations, maintenance, and inventory management.

By equipping conductors with iPads, CPKC can improve the efficiency of its operations, reduce operating costs, and enhance the overall customer experience. iPads are transforming rail operations by providing real-time information and enabling proactive decision-making. Pioneer-technology.com offers detailed analysis of these technologies, providing valuable insights into how iPads are revolutionizing rail operations.

CPKC conductors using iPads for real-time digital access to train assembly information, replacing paper-based processes.

CPKC conductors using iPads for real-time digital access to train assembly information, replacing paper-based processes.

26. FAQ Section

What is Positive Train Control (PTC)?

PTC is a safety system designed to prevent train accidents by automatically stopping or slowing a train to avoid collisions, speed restrictions, or unauthorized movements. It uses digital communication and GPS to monitor and control train movements.

How do drones improve rail safety?

Drones equipped with cameras and sensors can inspect tracks, bridges, and other infrastructure, identifying potential issues such as cracks, corrosion, or obstructions, enhancing safety and reducing the need for manual inspections.

What is the role of AI in rail transport?

AI is used for various purposes, including predictive maintenance, optimizing train schedules, enhancing safety systems, and improving fuel efficiency. AI algorithms analyze data to identify patterns and predict potential problems.

How do zero-emission cranes contribute to sustainable rail transport?

Zero-emission cranes reduce air pollution and greenhouse gas emissions by using electric power or alternative fuels instead of diesel. This helps to improve air quality and reduce the environmental impact of rail operations.

What are the benefits of real-time freight tracking?

Real-time freight tracking provides customers with detailed information about the location and status of their shipments, allowing them to monitor progress, plan logistics, and address any potential disruptions.

How do fuel management systems enhance fuel efficiency in trains?

Fuel management systems optimize train speed, spacing, and timing to reduce fuel consumption. They use real-time data and advanced algorithms to minimize fuel usage while maintaining on-time performance.

What is the significance of truck idling technology in rail yards?

Truck idling technology reduces truck wait times, minimizing emissions and improving throughput. Biometric scanners, video portals, and automated gate systems streamline rail yard operations and improve efficiency.

How is 3D printing used in the rail industry?

3D printing is used to create realistic training models, replacement parts, and customized components. This helps to improve training effectiveness, reduce maintenance costs, and enhance the overall efficiency of rail operations.

What are train inspection portals (TIPs)?

Train inspection portals (TIPs) use high-speed imaging and AI to identify wheel damage, brake issues, and structural wear as trains pass through at speed, replacing manual inspections and reducing downtime.

How do anti-idling systems reduce locomotive emissions?

Anti-idling systems automatically shut down locomotives when they are not in motion, reducing unnecessary fuel consumption and air pollution, promoting a more sustainable rail operation.

The rapid advancements in trains and technology are enhancing safety, streamlining operations, and reducing environmental impact within the rail industry. Stay ahead of the curve by visiting pioneer-technology.com. Discover our articles, get insights, and stay informed about the latest tech innovations in the USA. Are you ready to explore the future of trains and technology?