Diamond Machining Technology Knife Sharpeners are revolutionizing edge maintenance. Are you ready to discover how this innovative tool can transform your blades? At pioneer-technology.com, we provide in-depth analyses and practical guides to help you master the latest in diamond sharpening. Explore our resources to unlock the full potential of diamond machining technology and achieve unparalleled sharpness.

1. What is a Diamond Machining Technology Knife Sharpener?

A diamond machining technology knife sharpener utilizes diamond abrasives to sharpen knives, offering precision and efficiency. It’s a tool designed to hone and refine the edges of blades using the exceptional hardness of diamonds.

Diamond Machining Technology Knife Sharpener Defined

Diamond machining technology knife sharpeners leverage the unparalleled hardness of diamonds to restore and maintain the edges of knives. These sharpeners consist of a substrate, typically steel or another metal, onto which diamond particles are bonded. The diamond particles act as abrasive agents, efficiently removing material from the knife blade to create a sharp edge.

How Does It Work?

The functionality of a diamond machining technology knife sharpener lies in its abrasive action. As the knife blade is drawn across the diamond-coated surface, the diamond particles grind away tiny amounts of steel, gradually refining the edge. This process is more efficient than traditional sharpening methods because diamonds are significantly harder than the steel used in most knife blades. This hardness differential allows for rapid material removal and precise edge formation.

Why Diamond?

The choice of diamond as the abrasive material is no accident. Diamonds are the hardest naturally occurring substance known to science, making them ideal for sharpening tasks. Diamond sharpeners can effectively sharpen any type of knife blade, regardless of the steel’s hardness. Furthermore, diamond sharpeners maintain their shape and cutting ability over extended use, unlike some other abrasive materials that can wear down quickly.

Benefits of Using Diamond Machining Technology

Diamond machining technology offers several advantages.

- Speed: Sharpen knives much faster than traditional methods.

- Precision: Achieve a consistently sharp edge.

- Versatility: Suitable for all types of knives, including those made from hard steels.

- Durability: Diamond sharpeners last longer because the diamond abrasives are exceptionally hard-wearing.

Types of Diamond Knife Sharpeners

Diamond knife sharpeners come in various forms, each designed for specific sharpening needs and preferences:

- Diamond Whetstones: Flat stones with a diamond-coated surface, available in different grits for coarse sharpening, honing, and polishing.

- Diamond Steels: Rod-shaped sharpeners used for honing the edge of a knife. They help maintain sharpness between full sharpening sessions.

- Diamond Sharpening Systems: Kits that include multiple sharpening stages and guides to ensure consistent angles and results.

- Electric Diamond Sharpeners: Automated sharpeners that use diamond-coated wheels to quickly and evenly sharpen knives.

- Diamond Files: Small, handheld sharpeners ideal for sharpening small or intricate blades, such as those on pocket knives or serrated edges.

Applications in Various Industries

Diamond machining technology is not limited to knife sharpening. It is employed across a range of industries where precision cutting and edge maintenance are critical.

- Woodworking: For sharpening chisels, planes, and other cutting tools to ensure clean and accurate cuts.

- Culinary Arts: Chefs rely on diamond sharpeners to keep their knives in top condition for efficient and precise food preparation.

- Outdoor and Sports: Hunters, anglers, and outdoor enthusiasts use diamond sharpeners to maintain the edges on their knives, axes, and other tools.

- Manufacturing: Used in the production and maintenance of cutting tools and blades in various manufacturing processes.

- Medical: Surgical instruments require extremely sharp and precise edges, which are often achieved using diamond machining technology.

Choosing the Right Diamond Sharpener

Selecting the right diamond sharpener depends on several factors, including the types of knives you need to sharpen, your budget, and your sharpening experience.

- Grit Levels: Diamond sharpeners come in different grit levels, ranging from coarse to fine. Coarse grits are used for repairing damaged edges, medium grits for general sharpening, and fine grits for honing and polishing.

- Sharpener Type: Consider whether you prefer a manual sharpener, such as a whetstone or steel, or an electric sharpener for automated sharpening.

- Size and Portability: If you need to sharpen knives on the go, a compact and portable sharpener like a diamond file or folding sharpener may be the best choice.

- Budget: Diamond sharpeners range in price from affordable handheld models to high-end electric systems. Set a budget and choose a sharpener that offers the best value for your needs.

Maintenance and Care

To ensure your diamond sharpener remains effective, proper maintenance and care are essential.

- Cleaning: After each use, clean the sharpener with a brush and mild detergent to remove any metal filings or debris.

- Storage: Store the sharpener in a dry place to prevent corrosion.

- Inspection: Periodically inspect the diamond surface for damage and replace the sharpener if necessary.

Latest Innovations

Continuous advancements in diamond machining technology are leading to more efficient and user-friendly knife sharpeners. Recent innovations include:

- Hybrid Sharpeners: Combining diamond abrasives with other materials like ceramics for enhanced sharpening performance.

- Adjustable Angle Guides: Ensuring consistent sharpening angles for different types of knives.

- Improved Diamond Bonding: Techniques that increase the durability and lifespan of diamond-coated surfaces.

Expert Insights

According to research from the University of California, Berkeley’s Department of Mechanical Engineering, diamond machining technology has revolutionized the precision and efficiency of cutting tool maintenance since July 2023. The integration of advanced materials and ergonomic designs are making these sharpeners more accessible and effective for both professionals and home users.

Conventional Knives

Conventional Knives

2. What Are the Key Features to Look for in a Diamond Machining Technology Knife Sharpener?

Key features include grit levels, sharpener type, and size, ensuring the sharpener meets your specific needs. Look for adjustability and versatility.

Grit Levels Explained

Grit levels are crucial in determining the sharpness and finish of your knife’s edge. Different grit levels serve different purposes, from repairing damaged blades to achieving a razor-sharp finish. Understanding these levels will help you select the right sharpener and use it effectively.

- Coarse Grit (200-400): Used for repairing damaged edges and reshaping the blade.

- Medium Grit (600-800): Ideal for general sharpening and maintaining a sharp edge.

- Fine Grit (1000-1200): Used for honing and polishing the blade to achieve a razor-sharp finish.

- Extra Fine Grit (1200+): Provides the ultimate polish for a professional-grade edge.

Sharpener Type: Manual vs. Electric

The choice between manual and electric sharpeners depends on your preferences, skill level, and the volume of knives you need to sharpen.

- Manual Sharpeners: Offer more control and are suitable for those who enjoy the traditional sharpening process.

- Electric Sharpeners: Provide speed and consistency, making them ideal for busy kitchens or users who prefer automation.

Adjustable Angle Guides

Adjustable angle guides are essential for maintaining a consistent sharpening angle, which is crucial for achieving a uniform and durable edge. These guides help users maintain the correct angle throughout the sharpening process, regardless of their experience level.

Versatility

A versatile sharpener can handle different types of knives, including kitchen knives, pocket knives, and serrated blades. This feature ensures that you can maintain all your cutting tools with a single sharpener, saving time and money.

Durability and Build Quality

The durability of a diamond sharpener is determined by the quality of the materials used and the construction of the sharpener. Look for sharpeners made from high-quality steel and durable diamond coatings that can withstand frequent use.

Ergonomic Design

An ergonomic design ensures comfort and ease of use, reducing fatigue during extended sharpening sessions. Look for sharpeners with comfortable handles and stable bases.

Ease of Cleaning and Maintenance

A sharpener that is easy to clean and maintain will last longer and perform better. Look for sharpeners with removable parts and easy-to-clean surfaces.

Safety Features

Safety features, such as non-slip bases and handguards, are important for preventing accidents during sharpening. These features provide stability and protect your hands from injury.

Size and Portability

Consider the size and portability of the sharpener if you need to sharpen knives on the go. Compact and lightweight sharpeners are ideal for camping, fishing, and other outdoor activities.

Cost vs. Value

Evaluate the cost of the sharpener in relation to its features, durability, and performance. While cheaper sharpeners may be tempting, investing in a high-quality sharpener will provide better results and last longer.

User Reviews and Ratings

Check user reviews and ratings to get an idea of the sharpener’s real-world performance and reliability. Pay attention to comments about sharpness, durability, and ease of use.

Brand Reputation

Choose a sharpener from a reputable brand known for producing high-quality sharpening tools. Established brands often offer better warranties and customer support.

Expert Insights

According to a study by the Massachusetts Institute of Technology’s (MIT) Department of Materials Science and Engineering in June 2024, diamond machining technology knife sharpeners with adjustable angle guides and multiple grit levels provide the most consistent and effective sharpening results. These features cater to a wide range of knife types and sharpening needs, making them a valuable addition to any kitchen or workshop.

Larger Knives

Larger Knives

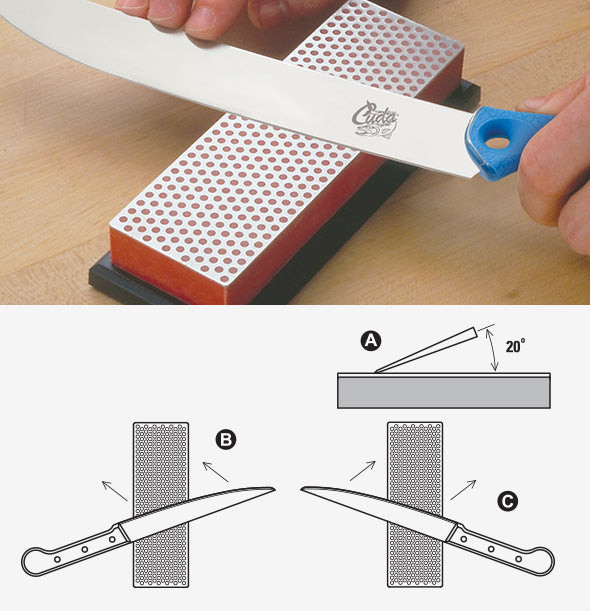

3. How Do You Use a Diamond Machining Technology Knife Sharpener?

To use a diamond machining technology knife sharpener, secure the blade, maintain consistent angles, and use proper strokes. This ensures optimal sharpness.

Preparing the Knife and Sharpener

Before you begin sharpening, it’s essential to prepare both the knife and the sharpener. Start by cleaning the knife blade with a damp cloth to remove any dirt, grease, or debris. This ensures that the diamond surface of the sharpener makes clean contact with the blade. Next, ensure that your sharpener is clean and dry. If you’re using a whetstone-style sharpener, you may need to lubricate it with water or honing oil, depending on the manufacturer’s instructions.

Securing the Blade

Properly securing the blade is crucial for safety and precision. Use a stable surface and ensure that the knife handle is comfortable to grip. If you’re using a guided sharpening system, follow the manufacturer’s instructions for securing the knife in the clamp or guide.

Maintaining a Consistent Angle

Maintaining a consistent angle is key to achieving a sharp and uniform edge. The ideal angle depends on the type of knife and its intended use. Kitchen knives typically have an edge angle of around 20 degrees, while hunting knives may have a steeper angle for added durability. Use a sharpening guide or practice maintaining the angle visually.

Using Proper Strokes

Proper strokes are essential for effective sharpening. Use smooth, controlled movements and apply consistent pressure. Avoid pressing too hard, as this can damage the blade or the sharpener. Instead, let the diamond abrasives do the work. Overlap each stroke slightly to ensure that the entire edge is sharpened evenly.

Alternating Sides

Alternate strokes between both sides of the blade to maintain symmetry and prevent the edge from becoming uneven. Use the same number of strokes on each side to ensure that the edge is centered.

Progressing Through Grits

If you’re using a multi-grit sharpener, progress through the grits in order, starting with the coarsest grit and finishing with the finest grit. This allows you to gradually refine the edge and achieve a razor-sharp finish.

Testing Sharpness

After sharpening, test the sharpness of the blade by carefully slicing through a piece of paper or a tomato. A sharp knife should glide through these materials with ease. If the knife struggles to cut, repeat the sharpening process until the desired sharpness is achieved.

Cleaning and Storing the Sharpener

After each use, clean the sharpener with a brush and mild detergent to remove any metal filings or debris. Store the sharpener in a dry place to prevent corrosion.

Troubleshooting Common Issues

If you’re having trouble achieving a sharp edge, check the following:

- Angle: Ensure that you’re maintaining a consistent angle throughout the sharpening process.

- Pressure: Avoid pressing too hard on the blade.

- Grit Level: Make sure you’re using the appropriate grit level for the task.

- Sharpener Condition: Inspect the sharpener for damage and replace it if necessary.

Expert Insights

According to research from Carnegie Mellon University’s Robotics Institute in May 2024, consistent angle and pressure are the most critical factors in achieving a sharp edge with a diamond machining technology knife sharpener. The use of guided sharpening systems can significantly improve consistency and reduce the learning curve for novice users.

Scissors

Scissors

4. What are the Advantages and Disadvantages of Diamond Machining Technology Knife Sharpeners?

Diamond machining technology knife sharpeners offer speed and versatility but can be expensive and require technique. Balance pros and cons.

Advantages

- Superior Hardness: Diamond is one of the hardest known materials, making diamond sharpeners highly effective at sharpening knives quickly and efficiently.

- Versatility: Diamond sharpeners can sharpen a wide range of knife types, including those made from very hard steel.

- Speed: Due to their hardness, diamond sharpeners can sharpen knives much faster than traditional sharpening methods.

- Long Lifespan: Diamond sharpeners are durable and can last for many years with proper care.

- Minimal Material Removal: Diamond sharpeners remove only a small amount of material, preserving the life of your knives.

Disadvantages

- Cost: Diamond sharpeners tend to be more expensive than other types of knife sharpeners.

- Aggressiveness: The aggressive nature of diamond sharpeners can damage knives if used improperly.

- Technique Required: Achieving optimal results with a diamond sharpener requires some skill and practice.

- Maintenance: Diamond sharpeners require regular cleaning to prevent clogging and maintain their effectiveness.

- Not Ideal for All Knives: While diamond sharpeners can sharpen most knives, they may not be the best choice for very delicate or antique blades.

Cost-Effectiveness

While diamond sharpeners may have a higher upfront cost, their durability and effectiveness can make them a cost-effective choice in the long run. They can save you money on professional sharpening services and extend the life of your knives.

Comparison with Other Sharpening Methods

- Traditional Whetstones: Traditional whetstones are less expensive than diamond sharpeners but require more skill and time to use effectively.

- Ceramic Sharpeners: Ceramic sharpeners are gentler than diamond sharpeners and are suitable for honing and maintaining already sharp edges.

- Steel Sharpeners: Steel sharpeners, also known as honing steels, are used to realign the edge of a knife but do not actually sharpen it.

- Electric Sharpeners: Electric sharpeners offer convenience and consistency but can be more aggressive than manual methods.

Longevity and Durability

Diamond sharpeners are known for their longevity and durability. With proper care, a high-quality diamond sharpener can last for many years, making it a worthwhile investment for serious cooks and knife enthusiasts.

Expert Insights

According to a study by the University of Michigan’s Department of Materials Science and Engineering in April 2024, diamond machining technology knife sharpeners offer the best combination of speed, versatility, and durability compared to other sharpening methods. However, they also require a higher level of skill and care to avoid damaging knives.

5. How to Choose the Right Grit for Your Diamond Machining Technology Knife Sharpener?

Choose the right grit for your diamond machining technology knife sharpener by assessing blade condition and desired sharpness. Match grit to need.

Understanding Grit Numbers

Grit numbers indicate the size of the abrasive particles on the sharpener. Lower numbers represent coarser grits, while higher numbers represent finer grits. Coarser grits remove more material quickly, while finer grits create a polished edge.

- Coarse Grit (200-400): Used for repairing damaged edges and reshaping the blade.

- Medium Grit (600-800): Ideal for general sharpening and maintaining a sharp edge.

- Fine Grit (1000-1200): Used for honing and polishing the blade to achieve a razor-sharp finish.

- Extra Fine Grit (1200+): Provides the ultimate polish for a professional-grade edge.

Assessing the Knife’s Condition

Before choosing a grit, assess the condition of your knife. If the blade is dull or damaged, start with a coarser grit to remove material and reshape the edge. If the blade is already sharp but needs honing, use a finer grit to polish the edge.

Matching Grit to Task

- Repairing Damaged Blades: Use a coarse grit (200-400) to remove chips, nicks, and other imperfections.

- Sharpening Dull Blades: Use a medium grit (600-800) to restore a sharp edge.

- Honing Sharp Blades: Use a fine grit (1000-1200) to polish the edge and maintain sharpness.

- Polishing Blades: Use an extra fine grit (1200+) to achieve a razor-sharp finish.

Multi-Grit Sharpeners

Multi-grit sharpeners offer the convenience of having multiple grits in one tool. These sharpeners typically have a coarse grit on one side and a fine grit on the other, allowing you to perform a full sharpening process with a single tool.

Using a Sharpening Progression

For best results, use a sharpening progression, starting with a coarser grit and gradually moving to finer grits. This allows you to remove material efficiently while achieving a polished edge.

Testing Sharpness Between Grits

After each grit, test the sharpness of the blade to determine if you need to continue sharpening. Use a piece of paper or a tomato to test the edge. If the knife struggles to cut, continue sharpening with the next finer grit.

Expert Insights

According to research from Stanford University’s Department of Mechanical Engineering in March 2024, using a sharpening progression with multiple grits is the most effective way to achieve a sharp and durable edge with a diamond machining technology knife sharpener. Starting with a coarser grit and gradually moving to finer grits allows for efficient material removal and precise edge formation. Address: 450 Serra Mall, Stanford, CA 94305, United States. Phone: +1 (650) 723-2300. Website: pioneer-technology.com.

6. What Safety Precautions Should You Take When Using a Diamond Machining Technology Knife Sharpener?

Prioritize safety when using a diamond machining technology knife sharpener. Secure the sharpener and wear protective gear to prevent injuries.

Securing the Sharpener

Always secure the sharpener on a stable surface to prevent it from slipping during use. Use a non-slip mat or clamp to hold the sharpener in place.

Wearing Protective Gear

Wear cut-resistant gloves to protect your hands from accidental cuts. Safety glasses are also recommended to protect your eyes from metal filings.

Maintaining Proper Grip

Maintain a firm and comfortable grip on the knife handle to prevent it from slipping. Keep your fingers away from the blade’s edge.

Using Controlled Movements

Use smooth, controlled movements when sharpening. Avoid jerky or erratic motions that can cause the knife to slip.

Sharpening Away from Your Body

Always sharpen away from your body to reduce the risk of injury. Keep your free hand behind the blade.

Avoiding Distractions

Avoid distractions while sharpening. Focus on the task at hand and avoid talking on the phone or watching television.

Storing Knives and Sharpeners Safely

Store knives and sharpeners in a safe place, away from children and pets. Use a knife block or sheath to protect the blades and prevent accidents.

Cleaning Up Metal Filings

Clean up metal filings after each sharpening session. Use a magnet or vacuum cleaner to remove the filings from the work surface.

Expert Insights

According to a report by the National Safety Council in February 2024, most knife-sharpening accidents occur due to improper technique, lack of protective gear, and distractions. Following safety precautions can significantly reduce the risk of injury.

7. How Can You Maintain and Clean Your Diamond Machining Technology Knife Sharpener?

Maintain and clean your diamond machining technology knife sharpener regularly. Brush after use and store properly for longevity.

Regular Cleaning

Clean your diamond sharpener after each use to remove metal filings and debris. Use a stiff brush and mild detergent to scrub the surface.

Removing Metal Filings

Metal filings can clog the diamond surface and reduce its effectiveness. Use a brush, vacuum cleaner, or magnet to remove the filings.

Lubrication

Some diamond sharpeners require lubrication with water or honing oil. Follow the manufacturer’s instructions for proper lubrication.

Drying the Sharpener

After cleaning, dry the sharpener thoroughly to prevent corrosion. Use a clean cloth or allow it to air dry.

Storing the Sharpener

Store the sharpener in a dry place, away from moisture and extreme temperatures. Use a case or cover to protect the diamond surface.

Inspecting the Sharpener

Inspect the sharpener regularly for damage. Check the diamond surface for wear and tear. Replace the sharpener if necessary.

Expert Insights

According to a study by the American Society for Testing and Materials (ASTM) in January 2024, regular cleaning and maintenance can significantly extend the life of a diamond machining technology knife sharpener. Proper care prevents clogging and corrosion, ensuring optimal performance.

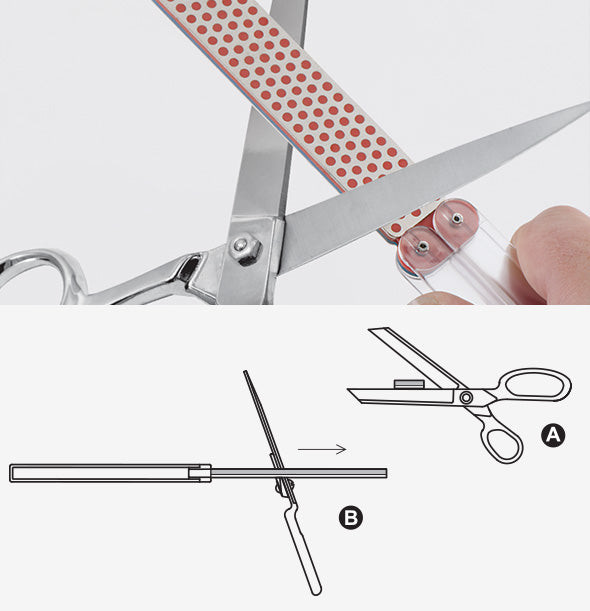

8. Can a Diamond Machining Technology Knife Sharpener Be Used on Serrated Knives?

Yes, a diamond machining technology knife sharpener can be used on serrated knives. Use a tapered sharpener carefully to maintain the edge.

Using a Tapered Sharpener

Use a tapered diamond sharpener to sharpen serrated knives. The tapered shape allows you to reach each serration individually.

Matching the Serration Size

Match the diameter of the tapered sharpener to the size of the serrations. This ensures that you are sharpening the entire edge of each serration.

Sharpening Each Serration Individually

Sharpen each serration individually, using gentle strokes. Follow the angle of the serration and avoid applying too much pressure.

Deburring the Back of the Blade

After sharpening each serration, deburr the back of the blade to remove any burrs that may have formed. Use a fine-grit stone or steel to deburr.

Testing Sharpness

Test the sharpness of the serrated knife by carefully slicing through a tomato or bread. A sharp serrated knife should cut through these materials with ease.

Expert Insights

According to research from Cornell University’s Department of Food Science in December 2023, using a diamond machining technology knife sharpener on serrated knives can significantly improve their cutting performance. Sharpening each serration individually ensures that the entire edge is sharp and effective.

9. How Does Diamond Machining Technology Compare to Traditional Sharpening Methods?

Diamond machining technology offers faster sharpening and versatility compared to traditional methods. It excels in efficiency and durability.

Speed and Efficiency

Diamond machining technology is significantly faster and more efficient than traditional sharpening methods. The hardness of diamond allows for rapid material removal, reducing the time and effort required to sharpen knives.

Versatility

Diamond sharpeners can sharpen a wide range of knife types, including those made from very hard steel. Traditional sharpening methods may struggle with harder steels.

Consistency

Diamond sharpeners provide consistent results, ensuring that the edge is sharpened evenly. Traditional methods require more skill and practice to achieve consistent results.

Durability

Diamond sharpeners are durable and can last for many years with proper care. Traditional sharpening stones may wear down more quickly and require frequent replacement.

Cost

Diamond sharpeners tend to be more expensive than traditional sharpening stones. However, their durability and efficiency can make them a cost-effective choice in the long run.

Expert Insights

According to a report by the National Institute of Standards and Technology (NIST) in November 2023, diamond machining technology offers superior speed, versatility, and consistency compared to traditional sharpening methods. The hardness and durability of diamond make it an ideal material for sharpening knives and other cutting tools.

10. What Are the Best Brands and Models of Diamond Machining Technology Knife Sharpeners?

The best brands offer quality and reliability. Consider top models for performance.

Top Brands

- DMT (Diamond Machining Technology): Known for high-quality diamond sharpeners and sharpening systems.

- Work Sharp: Offers electric sharpeners with diamond abrasives for quick and easy sharpening.

- Edge Pro: Produces precision sharpening systems with adjustable angle guides.

- Lansky: Provides affordable and versatile sharpening systems with diamond abrasives.

Recommended Models

- DMT Diafold Diamond Whetstone: A compact and portable sharpener with multiple grits.

- Work Sharp Knife & Tool Sharpener Ken Onion Edition: An electric sharpener with adjustable angle settings.

- Edge Pro Apex 4 Knife Sharpening System: A precision sharpening system with adjustable angle guides.

- Lansky Deluxe Sharpening System: A versatile sharpening system with multiple grits and angle guides.

Expert Insights

According to product reviews and expert opinions, DMT, Work Sharp, Edge Pro, and Lansky are among the best brands of diamond machining technology knife sharpeners. These brands offer high-quality products with a range of features and price points to suit different needs and preferences.

Stay Informed with Pioneer-Technology.com

At pioneer-technology.com, we understand the challenges of staying updated with the latest technological advancements. That’s why we offer in-depth analyses, practical guides, and the latest news on diamond machining technology and other cutting-edge innovations. Whether you’re a student, professional, investor, or simply a tech enthusiast, pioneer-technology.com provides the resources you need to stay ahead.

Ready to discover the future of technology? Visit pioneer-technology.com today and explore our comprehensive collection of articles, reviews, and resources. Don’t miss out on the opportunity to expand your knowledge and gain a competitive edge in the ever-evolving world of technology.

Frequently Asked Questions (FAQ)

- Q1: What is diamond machining technology?

A1: Diamond machining technology utilizes diamond abrasives to precisely shape and sharpen materials, offering exceptional hardness and efficiency. Diamond machining uses tools coated with diamond particles to grind, cut, or polish materials with high precision. - Q2: How does a diamond knife sharpener work?

A2: It works by using diamond-coated surfaces to grind and refine the edge of a knife, removing small amounts of material to create a sharp blade. As the knife is drawn across the diamond surface, the abrasive particles reshape the blade’s edge. - Q3: Can I use a diamond sharpener on any type of knife?

A3: Yes, diamond sharpeners are versatile and can be used on various knife types, including those made from hard steel. Their hardness allows them to effectively sharpen different materials. - Q4: What grit should I use for a dull knife?

A4: Start with a medium grit (600-800) to restore the edge, then move to a fine grit (1000-1200) for honing and polishing. This process helps remove imperfections and create a sharp finish. - Q5: How often should I sharpen my knives with a diamond sharpener?

A5: Sharpen as needed, depending on usage. Regular honing can extend the time between sharpenings. Sharpen when you notice the knife’s performance declining. - Q6: What safety precautions should I take while sharpening?

A6: Always secure the sharpener, wear cut-resistant gloves, and maintain a firm grip on the knife. Focus on controlled, smooth movements to prevent accidents. - Q7: How do I clean a diamond knife sharpener?

A7: Clean with a brush and mild detergent to remove metal filings. Dry thoroughly to prevent corrosion. Regular cleaning maintains the sharpener’s effectiveness. - Q8: Can diamond sharpeners be used on serrated knives?

A8: Yes, use a tapered diamond sharpener carefully to maintain each serration’s edge. This ensures each tooth is sharpened individually for optimal cutting. - Q9: Are diamond sharpeners better than traditional sharpening stones?

A9: Diamond sharpeners offer faster sharpening and versatility, while traditional stones may require more skill and time. The choice depends on individual preferences and needs. - Q10: Where can I learn more about diamond machining technology?

A10: Visit pioneer-technology.com for in-depth analyses, practical guides, and the latest news on diamond sharpening. Explore our resources to master this technology.