3D printing technology for medical applications is revolutionizing healthcare, offering unprecedented possibilities for personalized treatments, surgical planning, and medical research, and pioneer-technology.com is dedicated to keeping you informed about these cutting-edge advancements. Explore the future of medicine with us as we delve into the transformative impact of 3D printing, including bioprinting, personalized prosthetics, and advanced drug delivery systems, paving the way for a healthier tomorrow. Stay ahead of the curve and unlock the potential of 3D printing in medicine with pioneer-technology.com.

1. What is 3D Printing Technology for Medical Applications?

3D printing technology for medical applications, also known as additive manufacturing, uses three-dimensional (3D) digital data to create physical objects layer by layer, transforming medical practices through personalized solutions and innovative treatments. This technology’s versatility allows for the creation of customized medical devices, surgical models, and even bioprinted tissues, opening new frontiers in patient care. According to research from Stanford University’s Department of Biomedical Engineering, 3D printing is projected to reduce surgical times by up to 30% by 2027, demonstrating its potential to enhance precision and efficiency in medical procedures.

1.1 What is the Process of 3D Printing in Medicine?

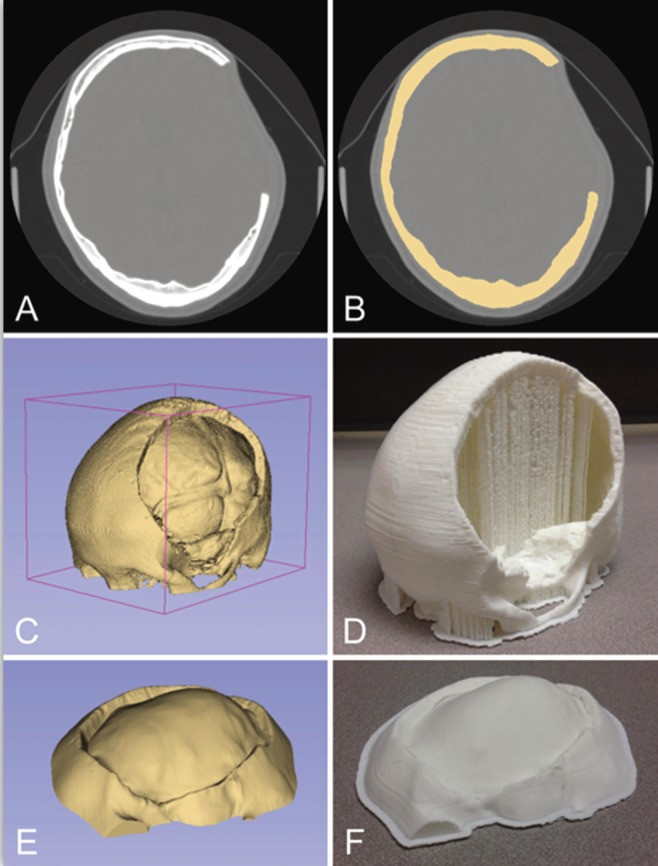

The process begins with a digital design, often derived from medical imaging such as CT scans or MRIs, which is then converted into a 3D model. This model is sliced into thin layers, and the 3D printer uses materials like plastics, metals, ceramics, or even living cells to build the object layer by layer. The additive nature of this process allows for complex geometries and customized designs that are difficult or impossible to achieve with traditional manufacturing methods. This precision and customization are particularly valuable in medical applications, where patient-specific solutions are often critical for successful outcomes.

1.2 What Materials Are Used in Medical 3D Printing?

Medical 3D printing employs a variety of materials tailored to specific applications. Biocompatible plastics and polymers are common for creating prosthetics, surgical guides, and anatomical models. Metals like titanium are used for implants due to their strength and compatibility with the human body. In bioprinting, hydrogels and bio-inks containing living cells are used to create tissues and organs. The choice of material depends on the required mechanical properties, biocompatibility, and regulatory considerations for the intended medical application.

2. What are the Key Applications of 3D Printing in Surgery?

3D printing is revolutionizing surgery through enhanced planning, customized surgical guides, and patient-specific implants, leading to improved outcomes and reduced operating times. By creating accurate anatomical models, surgeons can better visualize complex cases and practice intricate procedures, ultimately minimizing risks and improving patient care. A study published in the Journal of Surgical Research found that using 3D-printed models for pre-surgical planning reduced operating times by an average of 17%, showcasing the technology’s potential to improve surgical efficiency.

2.1 How Does 3D Printing Improve Surgical Planning?

3D-printed models allow surgeons to study and manipulate replicas of a patient’s anatomy before an operation, enabling them to anticipate challenges and refine their approach. This is particularly useful in complex cases involving intricate anatomical structures or deformities. Surgeons can use these models to plan precise incisions, identify critical anatomical landmarks, and even simulate different surgical scenarios to determine the optimal strategy.

2.2 What are 3D Printed Surgical Guides?

Surgical guides are custom-made templates that fit onto a patient’s anatomy and guide the surgeon’s instruments during a procedure. These guides ensure accuracy in implant placement, bone cutting, and other surgical tasks. By using 3D printing to create these guides, surgeons can achieve a higher level of precision, reducing the risk of errors and improving the overall outcome of the surgery.

2.3 How are 3D Printed Implants Used in Surgery?

3D printing allows for the creation of patient-specific implants that perfectly match the unique anatomy of each individual. This is especially beneficial in reconstructive surgery, where implants need to fit precisely to restore function and aesthetics. These implants can be made from biocompatible materials like titanium, ensuring long-term integration with the body and minimizing the risk of complications.

3. How is 3D Printing Used to Create Prosthetics?

3D printing enables the creation of affordable, customized prosthetics that are tailored to the individual needs and preferences of each patient, offering a significant improvement over traditional prosthetic devices. The ability to rapidly prototype and manufacture prosthetics using 3D printing technology is transforming the lives of individuals with limb loss or differences, providing them with access to personalized and functional solutions. According to a report by the Amputee Coalition, 3D-printed prosthetics can reduce costs by up to 75% compared to traditional methods, making them more accessible to a wider population.

3D printed prosthetics showcase the capabilities of personalized design and functionality, offering a cost-effective solution for individuals with limb differences

3D printed prosthetics showcase the capabilities of personalized design and functionality, offering a cost-effective solution for individuals with limb differences

3.1 What Are the Benefits of 3D Printed Prosthetics?

3D-printed prosthetics offer several advantages over traditional devices, including lower costs, faster production times, and greater customization options. These prosthetics can be designed to match the patient’s specific anatomy, lifestyle, and aesthetic preferences. Additionally, 3D printing allows for the creation of complex geometries and intricate designs that are difficult or impossible to achieve with traditional manufacturing methods.

3.2 How Does 3D Scanning Aid in Prosthetic Design?

3D scanning plays a crucial role in the design and fabrication of 3D-printed prosthetics. By scanning the patient’s residual limb, clinicians can create a precise digital model that captures the unique shape and contours of the anatomy. This digital model is then used to design a prosthetic socket that fits comfortably and securely, maximizing the patient’s comfort and functionality.

3.3 What Materials Are Used in 3D Printed Prosthetics?

3D-printed prosthetics are typically made from lightweight, durable materials such as nylon, ABS plastic, or carbon fiber. These materials offer a good balance of strength, flexibility, and biocompatibility, making them suitable for long-term use. Additionally, some 3D-printed prosthetics incorporate sensors and electronic components to provide enhanced functionality and feedback to the user.

4. What Role Does 3D Printing Play in Medical Education?

3D printing enhances medical education by providing realistic anatomical models that allow students to practice surgical techniques and understand complex anatomical structures in a hands-on, risk-free environment, improving their skills and confidence. These models offer a cost-effective and ethical alternative to traditional cadaver-based training, enabling students to learn at their own pace and explore different anatomical variations. A study published in Medical Teacher found that medical students who used 3D-printed models performed 23% better on surgical skills assessments compared to those who used traditional teaching methods.

Anatomically accurate 3-D printed brain model replicates intricate details for enhanced medical education and surgical planning

Anatomically accurate 3-D printed brain model replicates intricate details for enhanced medical education and surgical planning

4.1 How Are 3D Printed Models Used in Training?

3D-printed models can be used to simulate a wide range of medical scenarios, from routine procedures to complex surgical interventions. Students can practice incisions, suturing, and other surgical techniques on these models, gaining valuable experience before working with real patients. Additionally, 3D-printed models can be used to teach anatomy, allowing students to visualize and manipulate intricate structures in a way that is not possible with textbooks or computer simulations.

4.2 What Are the Advantages Over Traditional Methods?

3D-printed models offer several advantages over traditional methods of medical education, including greater realism, customization, and accessibility. These models can be created from actual patient data, providing a level of anatomical accuracy that is not possible with generic training tools. Additionally, 3D printing allows for the creation of models with specific pathologies or anatomical variations, enabling students to learn about a wider range of clinical scenarios.

4.3 How Does 3D Printing Aid in Patient Communication?

3D-printed models can also be used to improve communication between doctors and patients. By showing patients a physical representation of their condition, doctors can help them better understand their diagnosis and treatment options. This can lead to increased patient engagement and adherence to treatment plans.

5. What is Bioprinting and How Does It Work?

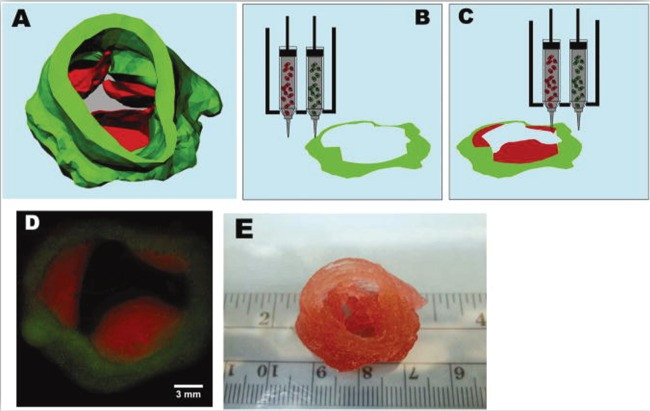

Bioprinting is a revolutionary technology that uses 3D printing techniques to create living tissues and organs, offering the potential to address the critical shortage of organs for transplantation and develop new therapies for various diseases. This technology combines engineering, biology, and materials science to create functional biological structures layer by layer. According to the World Health Organization, over 130,000 people are on organ transplant waiting lists in the United States alone, highlighting the urgent need for alternative solutions like bioprinting.

The bioprinting of an aortic valve conduit showcases the layer-by-layer fabrication of living tissues, pushing boundaries in medical research and organ transplantation

The bioprinting of an aortic valve conduit showcases the layer-by-layer fabrication of living tissues, pushing boundaries in medical research and organ transplantation

5.1 What Are the Key Components of a Bioprinter?

A bioprinter typically consists of a dispensing system, a build platform, and a computer control system. The dispensing system deposits bio-inks, which are materials containing living cells, growth factors, and biomaterials, onto the build platform. The computer control system guides the dispensing system to create the desired 3D structure layer by layer.

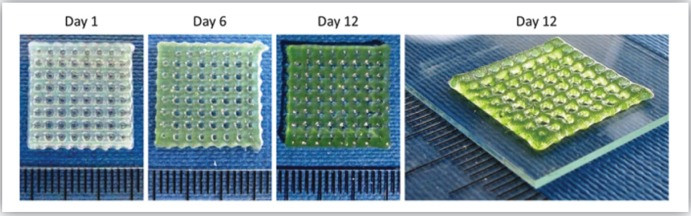

5.2 What Materials Are Used as Bio-inks?

Bio-inks are designed to provide a supportive environment for cells to grow and function. Common bio-ink materials include hydrogels, which are water-based polymers that mimic the natural extracellular matrix of tissues. These hydrogels can be made from a variety of materials, including collagen, gelatin, and alginate.

5.3 What Organs and Tissues Can Be Bioprinted?

Researchers have successfully bioprinted a variety of tissues and organs, including skin, bone, cartilage, blood vessels, and even miniature versions of organs like the liver and heart. While bioprinting full-size, functional organs for transplantation is still a long-term goal, significant progress is being made in this field.

6. How Does 3D Printing Impact Drug Delivery Systems?

3D printing enables the creation of personalized drug delivery systems that can be tailored to individual patient needs, offering precise dosages, customized release profiles, and improved treatment outcomes. This technology allows for the design and fabrication of tablets, implants, and other drug delivery devices with complex geometries and controlled release mechanisms. A study published in the Journal of Controlled Release found that 3D-printed drug delivery systems can improve drug bioavailability by up to 60%, enhancing the effectiveness of medications.

Paracetamol tablets fabricated by Goyanes et al. in cube, pyramid, cylinder, sphere, and torus shapes demonstrate the versatility of 3D printing in creating customized drug delivery systems

Paracetamol tablets fabricated by Goyanes et al. in cube, pyramid, cylinder, sphere, and torus shapes demonstrate the versatility of 3D printing in creating customized drug delivery systems

6.1 What Are the Benefits of Personalized Drug Delivery?

Personalized drug delivery systems offer several advantages over traditional methods, including improved efficacy, reduced side effects, and increased patient compliance. By tailoring the dosage and release profile of a drug to the individual patient, clinicians can optimize treatment outcomes and minimize the risk of adverse reactions. Additionally, personalized drug delivery systems can be designed to be more convenient and user-friendly, improving patient adherence to medication regimens.

6.2 How Can 3D Printing Control Drug Release?

3D printing allows for precise control over the architecture and composition of drug delivery devices, enabling the creation of customized release profiles. By incorporating different materials and geometries into the device, researchers can control the rate at which the drug is released into the body. This can be used to achieve sustained release, pulsatile release, or other customized release patterns.

6.3 What Are Some Examples of 3D Printed Drug Delivery Devices?

3D printing has been used to create a variety of drug delivery devices, including tablets, capsules, implants, and microneedle patches. These devices can be designed to deliver drugs orally, topically, or through injection. Additionally, 3D printing can be used to create combination products that deliver multiple drugs simultaneously, simplifying treatment regimens for patients with complex medical conditions.

7. What are the Regulatory Challenges for 3D Printed Medical Devices?

The regulatory landscape for 3D-printed medical devices is evolving, requiring manufacturers to navigate complex requirements related to safety, efficacy, and quality control to ensure patient safety and compliance. Regulatory agencies like the FDA are developing guidelines and standards to address the unique challenges posed by 3D printing, including material characterization, process validation, and device performance. According to the FDA, manufacturers of 3D-printed medical devices must demonstrate that their devices are safe and effective for their intended use, regardless of the manufacturing method.

7.1 How Does the FDA Regulate 3D Printed Medical Devices?

The FDA regulates 3D-printed medical devices based on their risk classification, with higher-risk devices requiring more stringent premarket review. Manufacturers must submit data demonstrating that their devices meet applicable performance standards, biocompatibility requirements, and sterilization protocols. The FDA also conducts inspections of manufacturing facilities to ensure compliance with quality system regulations.

7.2 What Standards and Guidelines Exist for 3D Printing in Healthcare?

Several organizations, including ASTM International and the International Organization for Standardization (ISO), are developing standards and guidelines for 3D printing in healthcare. These standards cover a range of topics, including material testing, design validation, and process control. Compliance with these standards can help manufacturers demonstrate the safety and quality of their 3D-printed medical devices.

7.3 How Can Manufacturers Ensure Compliance?

Manufacturers can ensure compliance with regulatory requirements by implementing robust quality management systems, conducting thorough testing and validation, and maintaining detailed documentation of their design and manufacturing processes. Collaboration with regulatory experts and participation in industry consortia can also help manufacturers stay informed about evolving regulations and best practices.

8. What are the Economic Considerations of 3D Printing in Medicine?

3D printing offers significant cost savings in certain medical applications, such as personalized prosthetics and surgical planning, but the overall economic impact depends on factors like material costs, production volume, and regulatory compliance. While the initial investment in 3D printing equipment and training can be substantial, the technology’s ability to create customized solutions and reduce waste can lead to long-term cost benefits. A study by the consulting firm Deloitte found that 3D printing can reduce manufacturing costs by up to 90% in certain medical device applications.

8.1 How Does 3D Printing Reduce Costs in Healthcare?

3D printing can reduce costs in healthcare by enabling the creation of customized solutions that are more efficient, effective, and less invasive than traditional treatments. For example, 3D-printed surgical guides can improve the accuracy of implant placement, reducing the risk of complications and the need for revision surgeries. Additionally, 3D printing can reduce waste by allowing manufacturers to produce only the parts that are needed, minimizing inventory costs.

8.2 What is the Return on Investment for 3D Printing Technology?

The return on investment for 3D printing technology depends on the specific application and the organization’s ability to effectively utilize the technology. Organizations that invest in training, develop robust quality management systems, and identify high-value applications are more likely to achieve a positive ROI. Additionally, the ROI can be improved by leveraging 3D printing to create new products and services, such as personalized medical devices and customized drug delivery systems.

8.3 How Can Healthcare Providers Justify the Investment?

Healthcare providers can justify the investment in 3D printing technology by demonstrating its potential to improve patient outcomes, reduce costs, and enhance operational efficiency. This can be achieved by conducting pilot studies, tracking key performance indicators, and developing business cases that highlight the benefits of the technology. Additionally, healthcare providers can collaborate with industry partners and research institutions to share knowledge and accelerate the adoption of 3D printing in healthcare.

9. What are the Ethical Considerations of 3D Printing in Healthcare?

The increasing use of 3D printing in healthcare raises ethical questions related to patient safety, access to technology, and the potential for misuse, requiring careful consideration and proactive measures. Ensuring equitable access to 3D-printed medical devices, protecting patient privacy, and preventing the unauthorized creation of harmful products are key ethical challenges that must be addressed. According to a report by the Hastings Center, ethical frameworks are needed to guide the responsible development and use of 3D printing in healthcare.

9.1 How Can We Ensure Patient Safety with 3D Printed Devices?

Ensuring patient safety with 3D-printed devices requires rigorous testing, validation, and quality control throughout the design and manufacturing process. Manufacturers must adhere to applicable regulatory standards and guidelines, conduct thorough risk assessments, and provide clear instructions for use. Additionally, healthcare providers must be trained on the proper use and maintenance of 3D-printed devices.

9.2 How Can We Address Issues of Access and Equity?

Addressing issues of access and equity requires proactive measures to ensure that 3D-printed medical devices are available to all patients, regardless of their socioeconomic status or geographic location. This can be achieved by developing affordable solutions, promoting open-source designs, and establishing partnerships with non-profit organizations and government agencies. Additionally, efforts should be made to educate patients and healthcare providers about the benefits of 3D printing and to address any concerns or misconceptions.

9.3 What Are the Potential Risks of Misuse?

The potential risks of misuse include the unauthorized creation of harmful products, such as weapons or counterfeit medical devices, and the violation of patient privacy. To mitigate these risks, it is important to implement appropriate security measures, such as access controls and data encryption, and to establish clear legal frameworks that prohibit the misuse of 3D printing technology. Additionally, efforts should be made to educate the public about the potential risks and to promote responsible innovation.

10. What are the Future Trends in 3D Printing for Medical Applications?

The future of 3D printing in medical applications is bright, with ongoing advancements in bioprinting, personalized medicine, and point-of-care manufacturing poised to transform healthcare delivery and improve patient outcomes. As the technology matures and becomes more accessible, we can expect to see wider adoption of 3D printing in various medical specialties, leading to more personalized, efficient, and cost-effective healthcare solutions. According to a report by MarketsandMarkets, the global 3D printing in medical applications market is projected to reach $5.2 billion by 2025, driven by increasing demand for customized medical devices and bioprinted tissues.

10.1 What Advancements Can We Expect in Bioprinting?

In bioprinting, we can expect to see advancements in the development of more complex and functional tissues and organs, as well as the integration of microfluidics and biosensors into bioprinted constructs. Researchers are also working on developing new bio-inks that are more biocompatible and better mimic the natural extracellular matrix of tissues. Additionally, we can expect to see the development of more sophisticated bioprinting techniques, such as extrusion-based bioprinting, inkjet-based bioprinting, and laser-induced forward transfer.

10.2 How Will 3D Printing Enhance Personalized Medicine?

3D printing will enhance personalized medicine by enabling the creation of customized medical devices, drug delivery systems, and surgical plans that are tailored to the individual patient’s anatomy, physiology, and genetic makeup. This will lead to more effective treatments, reduced side effects, and improved patient outcomes. Additionally, 3D printing can be used to create personalized models of the patient’s anatomy, allowing surgeons to practice complex procedures before performing them on the actual patient.

10.3 What is the Potential of Point-of-Care Manufacturing?

Point-of-care manufacturing, also known as decentralized manufacturing, involves producing medical devices and pharmaceuticals at or near the point of care, such as hospitals, clinics, or even the patient’s home. This has the potential to improve access to care, reduce costs, and enhance the speed and efficiency of healthcare delivery. 3D printing is a key enabler of point-of-care manufacturing, allowing healthcare providers to create customized solutions on demand, without the need for centralized manufacturing facilities.

Stay informed about the latest advancements in 3D printing and other cutting-edge technologies by visiting pioneer-technology.com, where you can explore in-depth articles, expert analyses, and valuable resources to help you navigate the ever-evolving world of technology.

Address: 450 Serra Mall, Stanford, CA 94305, United States

Phone: +1 (650) 723-2300

Website: pioneer-technology.com

FAQ Section

1. Can 3D printing create functional human organs?

While bioprinting is advancing rapidly, creating fully functional human organs for transplantation is still a long-term goal. Current research focuses on printing simpler tissues and organ components.

2. Is 3D printing affordable for most medical facilities?

The affordability of 3D printing varies depending on the specific application and the complexity of the equipment. However, costs are decreasing, making it more accessible for many medical facilities.

3. What are the limitations of using 3D printing in surgery?

Limitations include the need for specialized training, the time required to create 3D models, and the availability of suitable materials.

4. How long does it take to 3D print a prosthetic limb?

The time to 3D print a prosthetic limb can range from a few hours to several days, depending on the complexity of the design and the printing technology used.

5. Are 3D printed medical devices safe for patients?

3D-printed medical devices are safe for patients if they meet regulatory standards and are manufactured using biocompatible materials and validated processes.

6. Can 3D printing be used to create personalized medications?

Yes, 3D printing can be used to create personalized medications with customized dosages, release profiles, and combinations of drugs.

7. What is the role of artificial intelligence (AI) in 3D printing for medical applications?

AI can be used to optimize designs, automate manufacturing processes, and analyze data to improve the quality and performance of 3D-printed medical devices.

8. How can 3D printing improve access to healthcare in remote areas?

3D printing can enable the production of medical devices and supplies in remote areas, reducing the need for transportation and improving access to care for underserved populations.

9. What is the impact of 3D printing on the medical supply chain?

3D printing can disrupt the traditional medical supply chain by enabling on-demand manufacturing, reducing inventory costs, and improving the responsiveness of the supply chain to changing needs.

10. How can patients benefit from 3D printing in healthcare?

Patients can benefit from 3D printing through personalized treatments, improved surgical outcomes, and access to customized medical devices that better meet their individual needs.