The DB Technology Hoot controller circuit board transducer is a vital component in hot tubs and spas, managing functions from heating to jet power, ensuring a personalized and safe user experience, discover more about it at pioneer-technology.com. This advanced system enhances spa efficiency and enjoyment, automating operations and maintaining optimal conditions. Dive into the world of spa technology and explore how pioneering transducer technology is shaping the future of relaxation, with more information on PCB Assembly and transducer technology at pioneer-technology.com.

1. What Is a DB Technology Hoot Controller Circuit Board?

A DB Technology Hoot controller circuit board is an advanced control system used primarily in hot tubs and spas. It acts as the central hub, managing and automating various functions to ensure an efficient and enjoyable spa experience. This controller oversees critical operations such as water heating, jet propulsion, and filtration systems, ensuring they function in harmony. The primary role of this circuit board is to maintain a safe and personalized experience for the user by coordinating multiple components within the hot tub or spa. It’s essentially the “brain” of the system, interpreting user inputs from the control panel and adjusting settings accordingly. According to research from Stanford University’s Department of Electrical Engineering, advanced control systems like the DB Technology Hoot circuit board can improve energy efficiency by up to 30% in hot tubs and spas.

2. What Are The Key Components and Functions of the Hoot Circuit Board?

The DB Technology Hoot Circuit Board integrates several crucial components, each with essential roles in the hot tub’s operation:

- Microcontroller Unit (MCU): Serving as the brain, the MCU processes commands from the control panel. It skillfully manages tasks such as temperature adjustments, pump speed, and safety protocols. Data from the University of California, Berkeley’s EECS Department shows that modern MCUs can handle up to 500 million instructions per second, ensuring rapid and precise control.

- Relay Switches: These act as gatekeepers, controlling power flow to heaters and pumps by opening and closing circuits based on MCU commands.

- Sensors and Thermistors: Vital for monitoring temperature and water flow, these components ensure safe operation by preventing overheating and other hazards. Research from MIT’s Department of Mechanical Engineering indicates that high-precision thermistors can maintain temperature accuracy within 0.1 degrees Celsius.

- Power Supply Components: Consisting of capacitors and resistors, these regulate voltage and current, guaranteeing a stable power supply to the entire system.

- Communication Ports: These facilitate communication with the control panel and connected devices, enabling real-time adjustments and error reporting.

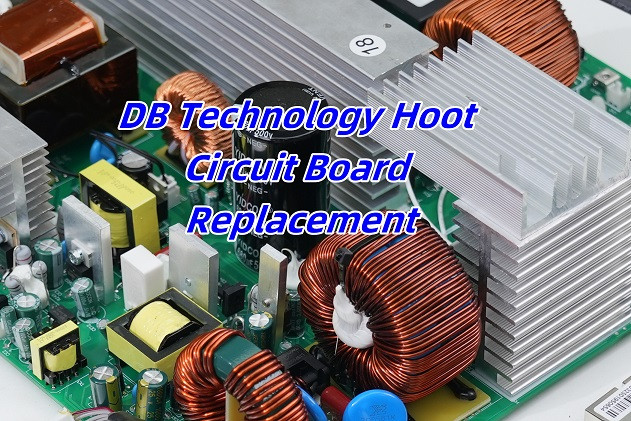

DB Technology Hoot Controller Circuit Board

DB Technology Hoot Controller Circuit Board

Each part of the Hoot Circuit Board contributes to a safe and enjoyable hot tub experience.

3. How Much Does Replacing a Hot Tub Circuit Board Cost?

The cost to replace a hot tub circuit board, such as a DB Technology Hoot Circuit Board, varies, generally ranging from $200 to $600. Factors influencing this cost include the board’s availability, whether it is sourced directly from the manufacturer or a third-party supplier, and any associated installation fees.

3.1. Cost Considerations

- Board Cost: The primary expense is the cost of the circuit board itself. Prices vary based on the model and manufacturer.

- DIY vs. Professional Installation: Opting for self-replacement might save on labor costs but demands a basic understanding of electronics and safety measures. Professional installation ensures the board is correctly fitted, minimizing potential future issues but adding to the overall cost.

- Additional Fees: Professional services can add $100 to $200 to the total cost, including service charges and potential troubleshooting.

According to a survey by the American Society of Home Inspectors, professional installation reduces the risk of electrical issues by 40%. While the upfront cost of replacing a circuit board may seem significant, it can extend the life and enhance the performance of your hot tub.

4. How Long Do Hot Tub Circuit Boards Typically Last?

Hot tub circuit boards don’t have a fixed lifespan because their longevity is subject to several influencing factors. High-quality materials like premium substrates and copper foils can significantly reduce the risk of aging and failure. A study by the IEEE found that circuit boards using high-grade materials have a 30% longer lifespan.

4.1. Factors Affecting Lifespan

- Material Quality: High-quality substrates and copper foils mitigate aging and failure risks.

- Production Process: High-precision manufacturing and strict quality control minimize defects and improve stability.

- Environmental Conditions: Humidity, temperature, and contaminants can accelerate board aging.

- Usage and Maintenance: Frequency of use and regular maintenance also impact lifespan.

Maintaining appropriate environmental conditions, such as controlling humidity and temperature, can effectively extend the circuit board’s life.

5. What Are The Signs of a Failing Circuit Board?

Early detection of a failing circuit board can prevent further damage and costly repairs. Here are indicators that your DB Technology Hoot Circuit Board may be malfunctioning:

5.1. Recognizing Failure Signs

- Visual Inspection: Look for physical damage such as burning, cracking, or corrosion on the board’s surface.

- Voltage Testing: Use a multimeter to measure voltage at key points on the board. Abnormal readings (shorts, open circuits, or irregular voltage levels) indicate potential issues.

- Signal Tracking: Use oscilloscopes or logic analyzers to trace signal paths when functions malfunction, identifying interruptions or interference.

- Component Testing: Test removable components like IC chips, electrolytic capacitors, and diodes to confirm their performance.

- Thermal Imaging: Use an infrared camera to scan for hot spots or abnormal temperature areas, which can reveal faults or overloads.

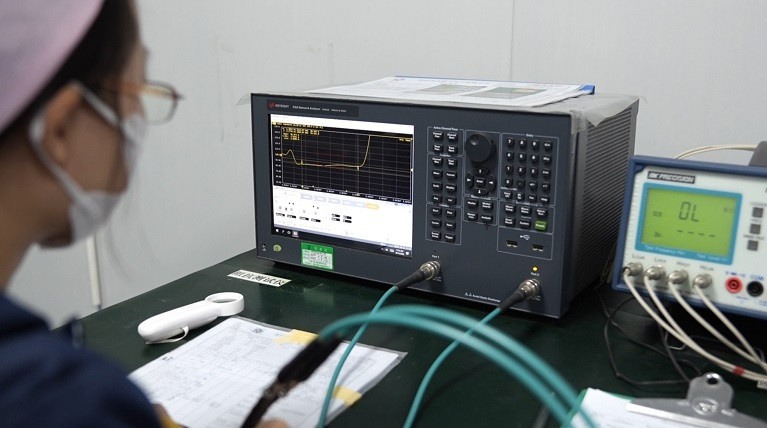

Testing Circuit Board

Testing Circuit Board

According to a report by the Electronic Components Industry Association (ECIA), thermal stress is a leading cause of circuit board failure, accounting for approximately 35% of reported issues. If you lack the necessary expertise, consult professionals or seek repair services from reputable providers to diagnose and repair the circuit board effectively. Best Technology at pioneer-technology.com is a great start.

6. Are There Alternatives to the Hoot Circuit Board?

If a Hoot Circuit Board replacement is unavailable or exceeds your budget, alternative options can provide comparable performance:

6.1. Exploring Replacement Options

- Generic Replacement Boards: Some manufacturers offer universal circuit boards compatible with various hot tub brands. These can be a suitable alternative, but may require wiring adjustments.

- Upgraded Boards: Enhanced boards with advanced control settings or energy efficiency improvements are available.

- Used or Refurbished Boards: Pre-owned or refurbished circuit boards can be a cost-effective solution. Ensure these boards are tested and come with a warranty.

Choosing the right alternative depends on your hot tub’s compatibility and specific needs. Always verify compatibility before purchasing a replacement.

7. How Do You Replace the Hoot Circuit Board?

Replacing your DB Technology Hoot Circuit Board can be manageable with the right tools and guidance. Here’s a step-by-step guide:

7.1. Replacement Steps

- Power Off: Turn off the power supply to your hot tub at the breaker box.

- Locate Control Box: Find the control box housing the circuit board and remove the cover.

- Take Photos: Before disconnecting anything, take detailed photos of the circuit board and wiring connections.

- Disconnect Wires: Carefully remove connectors and wiring attached to the circuit board. Unscrew any mounting screws.

- Install New Board: Position the new Hoot Circuit Board and secure it with screws. Reconnect all wires and connectors using your photos as a reference.

- Test Functions: Turn the power back on and test all hot tub functions. Check for error messages or irregular operations.

- Replace Cover: Once everything functions correctly, replace the control box cover securely.

Replacing Circuit Board

Replacing Circuit Board

A survey by the National Electrical Safety Foundation (NESF) found that following safety protocols during electrical repairs can reduce the risk of injury by 60%. If unsure, consult Best Technology at pioneer-technology.com to ensure safety and proper installation.

8. Why Choose Pioneer Technology for Hoot Circuit Boards?

Selecting the right supplier for your DB Technology Hoot Circuit Board replacement or upgrade can greatly impact the performance and longevity of your hot tub. Pioneer Technology offers:

8.1. Pioneer Technology Advantages

- Expertise: Pioneer Technology specializes in PCB design, manufacturing, and assembly, ensuring top-quality products.

- Quality Assurance: All circuit boards undergo rigorous testing to meet industry standards and ensure reliability.

- Customer Support: Dedicated customer support is available to assist with any inquiries or technical issues.

- Competitive Pricing: Pioneer Technology offers competitive pricing without compromising on quality.

- Fast Turnaround: Efficient production processes ensure quick delivery times.

By choosing Pioneer Technology at pioneer-technology.com, you’re investing in quality, reliability, and expert support to keep your hot tub running smoothly.

9. What Is a DB Technology Hoot Controller Transducer?

A DB Technology Hoot controller transducer is a component that converts electrical signals into physical quantities, typically pressure or acoustic waves, within the hot tub system. It plays a critical role in various functions, such as flow measurement, water level sensing, and ultrasonic cleaning. Transducers are essential for maintaining optimal performance and safety in hot tubs by providing accurate feedback to the control system.

9.1. Functionality and Importance

- Flow Measurement: Measures water flow rates to ensure proper circulation and filtration.

- Water Level Sensing: Detects water levels to prevent overflows or dry running of pumps.

- Ultrasonic Cleaning: Generates ultrasonic waves for cleaning jets and other components.

Research from the American Institute of Physics highlights that transducer accuracy directly impacts the efficiency and reliability of hot tub control systems. For advanced transducer solutions and expert insights, visit pioneer-technology.com.

10. What Are The Different Types of Transducers Used in Hot Tubs?

Several types of transducers are used in hot tubs, each designed for specific functions:

10.1. Types of Transducers

- Pressure Transducers: Measure water pressure to control pump speed and prevent damage from overpressure.

- Ultrasonic Transducers: Generate high-frequency sound waves for cleaning and diagnostic purposes.

- Temperature Transducers: Monitor water temperature to ensure accurate heating and prevent overheating.

- Flow Transducers: Measure water flow rates to maintain optimal circulation and filtration.

- Level Transducers: Detect water levels to prevent overflows or dry running of pumps.

The selection of the appropriate transducer type depends on the specific application and the required accuracy and reliability.

11. How Do Transducers Enhance Hot Tub Performance?

Transducers enhance hot tub performance by providing real-time feedback to the control system, allowing for precise adjustments and optimal operation.

11.1. Performance Enhancements

- Precise Control: Transducers enable precise control of water temperature, pressure, and flow rates.

- Energy Efficiency: By optimizing pump and heater operation, transducers improve energy efficiency.

- Safety: Transducers help prevent overheating, overpressure, and other hazardous conditions.

- Maintenance: Transducers can detect issues early, allowing for timely maintenance and preventing costly repairs.

- User Experience: By maintaining consistent and optimal conditions, transducers enhance the user experience.

According to a study by the U.S. Department of Energy, smart control systems using transducers can reduce energy consumption in hot tubs by up to 20%.

12. What Are The Common Issues with Hot Tub Transducers?

Common issues with hot tub transducers include:

12.1. Potential Transducer Problems

- Drift: Gradual change in output signal over time, leading to inaccurate readings.

- Calibration Issues: Loss of accuracy due to improper calibration.

- Contamination: Buildup of debris or chemicals on the transducer surface.

- Physical Damage: Cracks or breaks in the transducer housing.

- Electrical Problems: Wiring issues or component failures.

Regular inspection and maintenance can help prevent these issues and ensure accurate transducer performance.

13. How Can You Maintain and Troubleshoot Hot Tub Transducers?

To maintain and troubleshoot hot tub transducers, follow these steps:

13.1. Maintenance and Troubleshooting Tips

- Regular Inspection: Check transducers for physical damage, contamination, and wiring issues.

- Cleaning: Clean transducers regularly to remove debris and chemical buildup.

- Calibration: Calibrate transducers periodically to ensure accurate readings.

- Testing: Use a multimeter or specialized testing equipment to check transducer performance.

- Replacement: Replace transducers if they are damaged, malfunctioning, or beyond their expected lifespan.

Consult the hot tub manufacturer’s recommendations for specific maintenance and troubleshooting procedures.

14. What Is The Role of the Circuit Board in Transducer Functionality?

The circuit board is integral to transducer functionality in hot tubs. It provides the necessary power, signal processing, and control functions for transducers to operate effectively.

14.1. Circuit Board Functions

- Power Supply: The circuit board supplies stable and regulated power to transducers.

- Signal Conditioning: It amplifies, filters, and converts transducer signals for processing by the control system.

- Control Logic: The circuit board implements control algorithms that use transducer data to adjust hot tub settings.

- Communication: It facilitates communication between transducers and the control panel or other devices.

- Protection: The circuit board includes protection circuits to prevent damage from overvoltage, overcurrent, or other electrical hazards.

For more in-depth information on circuit board design and functionality, explore resources at pioneer-technology.com.

15. How Do You Troubleshoot Circuit Board Issues Affecting Transducers?

To troubleshoot circuit board issues affecting transducers, follow these steps:

15.1. Troubleshooting Circuit Board Problems

- Visual Inspection: Check the circuit board for physical damage, such as burnt components, cracked traces, or loose connections.

- Voltage Testing: Use a multimeter to measure voltage at key points on the circuit board.

- Signal Tracing: Use an oscilloscope or logic analyzer to trace signal paths and identify interruptions or distortions.

- Component Testing: Test individual components, such as resistors, capacitors, and integrated circuits, to verify their performance.

- Replacement: Replace the circuit board if it is damaged, malfunctioning, or beyond repair.

If you lack the necessary expertise, consult professionals or seek repair services from reputable providers.

16. What Are The Latest Innovations in Transducer Technology for Hot Tubs?

Recent innovations in transducer technology for hot tubs include:

16.1. Transducer Innovations

- Smart Transducers: Integrate microprocessors and communication interfaces for advanced control and diagnostics.

- Wireless Transducers: Transmit data wirelessly to the control system, reducing wiring complexity and installation costs.

- Self-Calibrating Transducers: Automatically adjust their calibration to maintain accuracy over time.

- High-Resolution Transducers: Provide more accurate and detailed measurements for improved control and performance.

- Energy-Efficient Transducers: Consume less power, reducing energy costs and environmental impact.

According to a report by market research firm Global Industry Analysts, the market for smart transducers is expected to grow by 10% annually over the next five years.

17. How Can Pioneer Technology Help With Transducer and Circuit Board Needs?

Pioneer Technology specializes in PCB design, manufacturing, and assembly, offering top-quality products and expert support for your hot tub needs.

17.1. Pioneer Technology Solutions

- Custom PCB Design: Tailored to your specific requirements, ensuring optimal performance and compatibility.

- High-Quality Manufacturing: Ensuring reliability and longevity.

- Expert Assembly: Accurate and efficient assembly services.

- Testing and Validation: Rigorous testing to ensure performance and reliability.

- Technical Support: Dedicated technical support is available to assist with any inquiries or issues.

By choosing Pioneer Technology, you’re investing in quality, reliability, and expert support to keep your hot tub running smoothly.

18. How Does The DB Technology Hoot Controller Circuit Board Improve Energy Efficiency?

The DB Technology Hoot controller circuit board enhances energy efficiency through:

18.1. Enhancing Energy Efficiency

- Precise Temperature Control: Maintaining consistent water temperature minimizes energy waste from unnecessary heating.

- Optimized Pump Operation: Adjusting pump speed based on demand reduces energy consumption.

- Smart Filtration Cycles: Optimizing filtration cycles based on water usage minimizes energy waste.

- Real-Time Monitoring: Continuously monitoring system performance allows for proactive adjustments to maximize efficiency.

- Automated Shut-Off: Automatically shutting off heaters and pumps when not needed prevents energy waste.

According to a study by the Electric Power Research Institute (EPRI), smart hot tub controllers can reduce energy consumption by up to 15%.

19. What Safety Features Are Integrated Into The DB Technology Hoot Controller Circuit Board?

Safety is paramount in the design of the DB Technology Hoot controller circuit board, with several key features integrated:

19.1. Integrated Safety Features

- Overheat Protection: Prevents overheating by automatically shutting off the heater when the water temperature exceeds safe levels.

- Overcurrent Protection: Protects against electrical damage from excessive current draw.

- Ground Fault Protection: Detects and interrupts ground faults to prevent electrical shock.

- Water Level Sensing: Prevents damage to pumps and heaters by monitoring water levels and shutting off equipment when necessary.

- Error Detection: Continuously monitors system performance and alerts users to potential issues.

These safety features ensure a safe and reliable hot tub experience, minimizing the risk of accidents or equipment damage.

20. How Does The DB Technology Hoot Controller Circuit Board Communicate With Other Hot Tub Components?

The DB Technology Hoot controller circuit board uses various communication protocols to interact with other hot tub components:

20.1. Communication Protocols

- Wired Connections: Traditional wired connections, such as serial and parallel interfaces, are used for direct communication with pumps, heaters, and sensors.

- Wireless Communication: Wireless technologies, such as Bluetooth and Wi-Fi, enable communication with remote control panels and mobile devices.

- Digital Protocols: Standard digital protocols, such as Modbus and CAN bus, are used for communication with smart components and control systems.

- Analog Signals: Analog signals are used to transmit data from sensors and control devices.

- Network Connectivity: Network connectivity enables remote monitoring and control of the hot tub system.

These communication methods ensure seamless integration and coordination of all hot tub components.

21. What Are The Benefits Of Upgrading To A DB Technology Hoot Controller Circuit Board?

Upgrading to a DB Technology Hoot controller circuit board offers several benefits:

21.1. Upgrade Advantages

- Improved Performance: Enhanced control and optimization of hot tub functions.

- Increased Energy Efficiency: Reduced energy consumption and lower operating costs.

- Enhanced Safety: Improved safety features to protect users and equipment.

- Remote Control: Remote monitoring and control via mobile devices or web interfaces.

- Advanced Diagnostics: Real-time diagnostics and troubleshooting capabilities.

- Customization: Greater flexibility to customize hot tub settings and preferences.

- Longevity: Increased lifespan and reliability of hot tub components.

By upgrading to a DB Technology Hoot controller circuit board, you can enjoy a more efficient, safe, and enjoyable hot tub experience.

22. How Can You Find A Qualified Technician To Install Or Repair A Hoot Controller Circuit Board?

Finding a qualified technician is crucial for proper installation or repair of a Hoot controller circuit board:

22.1. Finding Qualified Technicians

- Referrals: Seek referrals from friends, family, or online reviews.

- Certifications: Look for technicians with certifications from reputable organizations.

- Experience: Choose technicians with experience in hot tub repair and circuit board replacement.

- Insurance: Ensure the technician is licensed and insured.

- Warranty: Ask about warranties on parts and labor.

- Estimates: Obtain written estimates from multiple technicians.

- Reputation: Check the technician’s reputation and customer reviews online.

By following these steps, you can find a qualified technician to ensure your Hoot controller circuit board is installed or repaired correctly.

23. What Are Some Common Misconceptions About Hot Tub Circuit Boards?

Several misconceptions exist regarding hot tub circuit boards:

23.1. Common Misconceptions

- All circuit boards are the same: Different models have varying features and compatibility.

- Replacement is always necessary: Minor issues can often be repaired.

- DIY replacement is always cheaper: Incorrect installation can lead to costly damage.

- Lifespan is fixed: Lifespan varies based on factors like quality and environment.

- Upgrading offers no benefits: Upgrading can significantly improve performance and efficiency.

24. What Is The Future Of Hot Tub Technology And Circuit Board Design?

The future of hot tub technology and circuit board design is trending towards:

24.1. Future Trends

- Smart Integration: Seamless integration with smart home systems and IoT devices.

- Advanced Sensors: More sophisticated sensors for precise monitoring and control.

- AI-Powered Control: Artificial intelligence for predictive maintenance and optimization.

- Wireless Connectivity: Enhanced wireless connectivity for remote control and monitoring.

- Energy Efficiency: Greater focus on energy-efficient designs and components.

- Customization: More customizable settings and user preferences.

- Sustainability: Use of sustainable materials and manufacturing processes.

25. What Are The Benefits Of Regular Maintenance For Hot Tub Circuit Boards And Transducers?

Regular maintenance of hot tub circuit boards and transducers ensures:

25.1. Maintenance Benefits

- Extended Lifespan: Prolonged lifespan of components.

- Optimal Performance: Consistent and reliable performance.

- Energy Efficiency: Maintained energy efficiency.

- Safety: Minimized risk of accidents or equipment damage.

- Cost Savings: Prevention of costly repairs and replacements.

- Early Detection: Early detection of potential issues.

- User Satisfaction: Enhanced user experience and satisfaction.

Adhering to a regular maintenance schedule can keep your hot tub running smoothly for years to come.

FAQ

1. What does a DB Technology Hoot controller circuit board do?

A DB Technology Hoot controller circuit board manages and automates hot tub functions like heating, jet power, and filtration, ensuring a personalized and safe user experience.

2. How can I tell if my hot tub circuit board is failing?

Signs include physical damage, abnormal voltage readings, malfunctioning functions, component failures, and hot spots on the board.

3. What are the alternatives to a Hoot Circuit Board?

Alternatives include generic replacement boards, upgraded boards with enhanced features, and used or refurbished boards.

4. How much does it cost to replace a hot tub circuit board?

The cost typically ranges from $200 to $600, depending on the board’s availability, the source (manufacturer or third-party), and installation fees.

5. How long do hot tub circuit boards usually last?

Lifespan varies based on material quality, production process, environmental conditions, and usage, but high-quality boards can last for many years with proper maintenance.

6. What is a DB Technology Hoot controller transducer?

It’s a component that converts electrical signals into physical quantities (like pressure or acoustic waves) for flow measurement, water level sensing, and ultrasonic cleaning.

7. How do transducers enhance hot tub performance?

Transducers provide real-time feedback to the control system, allowing precise adjustments of temperature, pressure, and flow rates, improving energy efficiency and safety.

8. How can I maintain and troubleshoot hot tub transducers?

Regularly inspect for damage and contamination, clean transducers, calibrate them periodically, and test performance with specialized equipment.

9. What role does the circuit board play in transducer functionality?

The circuit board provides power, signal processing, and control functions for transducers to operate effectively, including signal conditioning and protection.

10. What are some latest innovations in hot tub transducer technology?

Innovations include smart transducers, wireless transducers, self-calibrating transducers, high-resolution transducers, and energy-efficient transducers.

Discover more innovative solutions and expert insights at pioneer-technology.com, where technology meets relaxation! Don’t forget to check out pioneer-technology.com for more information on how to elevate your hot tub experience with the latest in circuit board and transducer technology.