Epner Technology stands out as a leader in specification electroplating, offering solutions that cater to various industries, which you can explore further at pioneer-technology.com. With a rich history and a commitment to innovation, Epner Technology’s advanced plating processes deliver superior performance and reliability, addressing the evolving needs of modern technology and opening doors to countless opportunities. Check out pioneer-technology.com for detailed insights, expert analyses, and the latest updates on electroplating advancements.

Table of Contents

- What is Epner Technology and What Does It Offer?

- Who is the New President of Epner Technology?

- What is Laser Gold and Why is it Important?

- What Are the Key Applications of Laser Gold Plating?

- What Industries Benefit from Epner Technology’s Plating Solutions?

- What is Specification Plating and Why is it Necessary?

- How Does Epner Technology Contribute to Space Exploration?

- What are Light Pipes and How Does Epner Technology Enhance Them?

- What is Laser Black and How is it Used?

- What is High-Q Silver and What Are its Advantages?

- How Does Epner Technology Support the Arts?

- What is Laser Gold Thermal Foil and Where is it Used?

- What Quality Standards Does Epner Technology Maintain?

- What Makes Epner Technology Unique in the Electroplating Industry?

- How Can Epner Technology Help Solve Specific Technical Challenges?

- What Customer Testimonials Highlight Epner Technology’s Success?

- What Innovations Can We Expect from Epner Technology in the Future?

- How Does Epner Technology Ensure Excellent Communication with Clients?

- What are the Key Benefits of Visiting pioneer-technology.com?

- Frequently Asked Questions (FAQs) About Epner Technology

1. What is Epner Technology and What Does It Offer?

Epner Technology is a leading electroplating company specializing in high-tech specification plating, offering advanced solutions like Laser Gold, High-Q Silver, and Laser Black for industries requiring precision and performance. The company provides specialized plating services for industries ranging from aerospace and defense to telecommunications and the arts. According to the University of Leicester in the UK, Epner Technology is one of the most technically sophisticated electroplating companies globally, and its innovative processes like Laser Gold have set industry standards.

Delving deeper, Epner Technology distinguishes itself by:

-

Proprietary Processes: Laser Gold, known for its exceptional infrared (IR) reflectivity, has been selected by the National Institute of Standards and Technology (NIST) for their catalog of Standard Reference Materials.

-

Extensive Experience: Founded in 1910, Epner has over 80 years of experience in high-tech plating, including critical work on early radar systems.

-

Customer Communication: Epner prioritizes understanding customer requirements to tailor solutions effectively.

-

Diverse Applications: Their coatings are used in space satellites, the Academy Awards Oscars, and various other high-tech applications.

Want to explore more about advanced materials and their applications? Visit pioneer-technology.com for comprehensive articles, expert insights, and the latest technological breakthroughs.

2. Who is the New President of Epner Technology?

Paul Brancato is the new President of Epner Technology, bringing a fresh perspective and commitment to maintaining the company’s high standards of technical excellence and customer communication. As President, Brancato aims to uphold Epner Technology’s legacy of innovation and quality in specification electroplating.

Brancato’s vision includes:

-

Continued Innovation: Focusing on developing and refining proprietary plating processes.

-

Customer Focus: Ensuring clear communication and understanding of customer needs.

-

Industry Leadership: Maintaining Epner Technology’s position as a leader in the electroplating industry.

-

Quality Assurance: Upholding the highest standards of quality and precision in all plating services.

For more information on technology leadership and industry advancements, check out pioneer-technology.com.

3. What is Laser Gold and Why is it Important?

Laser Gold is a proprietary, electrochemically deposited gold coating developed by Epner Technology, known for its exceptional infrared (IR) reflectivity, ultra-low emissivity, and hardness. Its importance stems from its ability to enhance the performance and efficiency of various technologies across industries. Laser Gold achieves the theoretical IR reflectivity and ultra-low emissivity of pure gold, making it invaluable for applications requiring optimal thermal control and reflectivity.

Laser Gold plating enhances the thermal efficiency of components, crucial for aerospace applications

Laser Gold plating enhances the thermal efficiency of components, crucial for aerospace applications

Key attributes of Laser Gold include:

- High Reflectivity: Maximizes the reflection of infrared radiation.

- Low Emissivity: Minimizes heat emission, critical for thermal management.

- Hardness: With a Knoop hardness of nearly 200, it is three times harder than other pure gold plating processes.

- Purity: Composed of 24 karat gold, ensuring the highest quality and performance.

Laser Gold’s unique properties make it essential in space technology, scientific instruments, and even the arts, providing reliable and efficient performance in demanding environments. Explore further into the world of advanced materials at pioneer-technology.com and uncover more innovative applications.

4. What Are the Key Applications of Laser Gold Plating?

Laser Gold plating is used in several critical applications, including thermal control in spacecraft, enhancing the reflectivity of scientific instruments, and even adorning prestigious awards like the Oscars. Due to its superior IR reflectivity and hardness, Laser Gold ensures optimal performance and longevity in these diverse fields.

Here’s a breakdown of its key applications:

-

Spacecraft Thermal Control: NASA specifies Laser Gold for thermal management on spacecraft like the GOES weather satellites, Hubble Space Telescope, and James Webb Space Telescope.

-

Scientific Instruments: Enhances the efficiency of instruments requiring high IR reflectivity, such as those used in research and development.

-

Awards and Recognition: The Academy Awards uses Laser Gold to coat the Oscars, symbolizing quality and prestige.

-

Industrial Applications: Improves the efficiency of chemical reaction vessels and other industrial equipment.

Laser Gold’s versatility highlights its significance in both high-tech and artistic domains. For more on how advanced materials are shaping industries, visit pioneer-technology.com.

5. What Industries Benefit from Epner Technology’s Plating Solutions?

Epner Technology’s plating solutions benefit a wide range of industries, including aerospace, defense, telecommunications, automotive, and the arts, by providing coatings that enhance performance, durability, and aesthetic appeal. These industries rely on Epner Technology for specialized plating that meets stringent requirements and improves the functionality of their products.

Industries that particularly benefit include:

- Aerospace: For thermal control and reflectivity in spacecraft and satellites.

- Defense: For critical components requiring high precision and reliability.

- Telecommunications: For enhancing the performance of microwave components.

- Automotive: For thermal barriers and heat management in high-performance vehicles.

- Arts: For adding a touch of elegance and durability to sculptures and artworks.

Epner Technology's plating solutions enhance the durability and aesthetic appeal of artistic creations

Epner Technology's plating solutions enhance the durability and aesthetic appeal of artistic creations

The diverse applications of Epner Technology’s plating solutions underscore their value across various sectors. Stay updated with the latest industry trends and technological advancements at pioneer-technology.com.

6. What is Specification Plating and Why is it Necessary?

Specification plating involves applying metal coatings to meet specific industry, regulatory, or customer requirements, ensuring that the plated components achieve the desired performance, durability, and reliability. It is necessary to ensure that plated parts meet stringent standards for performance and quality. Epner Technology adheres to all applicable ASTM, AMS, MIL, and Prime Contractor specifications, maintaining a Quality System that implements ISO 9001:2008.

Key aspects of specification plating include:

- Compliance: Meeting industry standards such as ASTM, AMS, and MIL specifications.

- Quality Control: Ensuring coatings meet specific performance criteria.

- Customization: Tailoring plating processes to meet unique customer requirements.

- Reliability: Providing consistent and dependable results for critical applications.

For insights into quality standards and compliance in technology, visit pioneer-technology.com.

7. How Does Epner Technology Contribute to Space Exploration?

Epner Technology contributes significantly to space exploration by providing specialized coatings like Laser Gold for thermal control and reflectivity on spacecraft and satellites, ensuring optimal performance in the harsh conditions of space. Their coatings are used on critical components of spacecraft, helping to maintain stable temperatures and reflect infrared radiation, which is essential for the functioning of instruments and the overall success of space missions.

Notable contributions include:

- Thermal Management: Laser Gold is used on satellites like the GOES weather satellites to control temperature.

- Enhanced Reflectivity: Coatings on the Hubble and James Webb Space Telescopes improve the performance of infrared cameras.

- Structural Components: Laser Gold is applied to structural rings separating satellites for the Multiscale Magnospheric spacecraft (MMS) mission.

Epner Technology’s contributions highlight the critical role of advanced materials in advancing space exploration. Explore more about technology in space at pioneer-technology.com.

8. What are Light Pipes and How Does Epner Technology Enhance Them?

Light pipes, also known as hollow waveguides or homogenizers, are tubes lined with a highly polished, infrared-reflective coating, typically used to guide and homogenize light in various applications. Epner Technology enhances light pipes by lining them with Laser Gold, a coating known for its exceptional IR reflectivity, which maximizes the efficiency of light transmission.

Key benefits of Epner Technology’s light pipes include:

- High Reflectivity: Laser Gold lining ensures maximum light reflection.

- Custom Design: Tailored designs to meet specific application requirements.

- Precision Manufacturing: Achieving ultra-low surface roughness measured in Ångströms.

- Versatile Applications: Used in gas sensors and other instruments requiring efficient light transmission.

Discover more about light pipe technology and its applications at pioneer-technology.com.

9. What is Laser Black and How is it Used?

Laser Black is a velvet-like metallic oxide coating developed by Epner Technology, known for its ability to absorb light and prevent out-gassing. It is used in applications where light absorption and thermal stability are critical. Laser Black can be applied to any substrate that can withstand 100°C and is often used in space instruments and other high-tech applications where stray light needs to be minimized.

Key features of Laser Black include:

- High Absorption: Effectively absorbs light, minimizing reflections.

- Thermal Stability: Inorganic coating that does not out-gas.

- Versatile Application: Can be applied to various substrates.

- Stray Light Reduction: Ideal for use in optical instruments.

For more on advanced coatings and their applications, visit pioneer-technology.com.

10. What is High-Q Silver and What Are its Advantages?

High-Q Silver is an ultra-pure, un-brightened silver coating offered by Epner Technology, known for its enhanced crystal structure achieved through grain refiners rather than organic brighteners. It provides superior electrical conductivity and reflectivity, making it ideal for applications in telecommunications and electronics.

Key advantages of High-Q Silver include:

- High Purity: Ensures excellent electrical and thermal conductivity.

- Enhanced Crystal Structure: Achieved through grain refiners for superior performance.

- Matte Finish: Provides a non-reflective surface.

- Versatile Applications: Used in microwave components and other electronic devices.

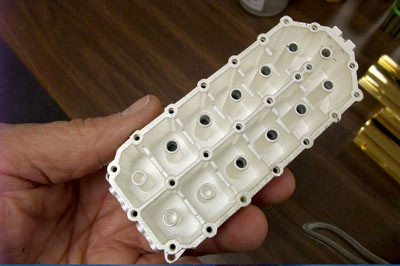

High-Q Silver coating on a plastic microwave filter housing, enhancing its performance in telecommunications

High-Q Silver coating on a plastic microwave filter housing, enhancing its performance in telecommunications

Learn more about the benefits of High-Q Silver and other advanced materials at pioneer-technology.com.

11. How Does Epner Technology Support the Arts?

Epner Technology supports the arts by applying its high-tech know-how to create stunning and durable finishes for sculptures, artworks, and jewelry. The company set up a division dedicated to collaborating with artists, offering specialized plating services that enhance the aesthetic appeal and longevity of their creations.

Key contributions to the arts include:

- Laser Gold Plating: Adding a touch of elegance and durability to sculptures.

- Custom Finishes: Tailoring plating processes to meet the unique vision of artists.

- Collaboration: Working closely with artists to bring their creative ideas to life.

- Enhanced Durability: Ensuring artworks withstand the test of time.

Discover how technology enhances art and creativity at pioneer-technology.com.

12. What is Laser Gold Thermal Foil and Where is it Used?

Laser Gold Thermal Foil is a copper foil coated with Laser Gold, designed to provide ultimate thermal control and protection in high-heat environments, commonly used in the automotive racing industry to protect carbon fiber components from engine and exhaust heat. The foil’s high reflectivity and low emissivity make it an effective thermal barrier.

Key features and applications include:

- High Reflectivity: Laser Gold coating reflects heat effectively.

- Thermal Barrier: Protects components from extreme temperatures.

- Automotive Racing: Used to shield carbon fiber parts from engine and exhaust heat.

- Versatile Applications: Can be used in any application requiring thermal management.

For more insights into thermal management technologies, explore pioneer-technology.com.

13. What Quality Standards Does Epner Technology Maintain?

Epner Technology maintains rigorous quality standards by adhering to all applicable ASTM, AMS, MIL, and Prime Contractor specifications. The company operates a Quality System that implements ISO 9001:2008, ensuring that all plating processes meet the highest standards of performance, reliability, and consistency.

Key quality standards include:

- ISO 9001:2008: Certified Quality Management System.

- ASTM, AMS, MIL Specifications: Compliance with industry standards.

- Prime Contractor Specifications: Meeting specific requirements of major contractors.

- Continuous Improvement: Ongoing efforts to enhance quality and performance.

For more on quality assurance and industry standards, visit pioneer-technology.com.

14. What Makes Epner Technology Unique in the Electroplating Industry?

Epner Technology is unique in the electroplating industry due to its proprietary processes like Laser Gold, its long history of technical innovation, and its commitment to customer communication and satisfaction. The combination of these factors sets Epner Technology apart as a leader in high-tech specification plating.

Key differentiating factors include:

- Proprietary Technologies: Laser Gold and other unique plating processes.

- Technical Expertise: Over 80 years of experience in high-tech plating.

- Customer Focus: Prioritizing clear communication and understanding customer needs.

- Diverse Applications: Serving a wide range of industries with specialized plating solutions.

Explore the innovations that set technology leaders apart at pioneer-technology.com.

15. How Can Epner Technology Help Solve Specific Technical Challenges?

Epner Technology excels at solving specific technical challenges by offering customized plating solutions tailored to meet unique customer requirements. Whether it’s enhancing thermal control in spacecraft, improving the reflectivity of scientific instruments, or providing durable finishes for artistic creations, Epner Technology’s expertise and proprietary processes deliver optimal results.

Examples of problem-solving capabilities:

- Thermal Management: Providing Laser Gold coatings for efficient heat control.

- Enhanced Reflectivity: Improving the performance of optical instruments with specialized coatings.

- Durability: Creating long-lasting finishes for high-wear applications.

- Custom Solutions: Tailoring plating processes to meet specific technical needs.

For insights into innovative solutions and technology problem-solving, visit pioneer-technology.com.

16. What Customer Testimonials Highlight Epner Technology’s Success?

Customer testimonials frequently highlight Epner Technology’s success in delivering flawless plating, meeting impossible schedules, and providing exceptional quality that exceeds expectations. These testimonials underscore Epner Technology’s commitment to excellence and customer satisfaction.

Key testimonials include:

- NASA-Goddard: Praising flawless Laser Gold plating and on-time delivery against an “impossible” schedule.

- National Oceanic and Atmospheric Admin.: Noting nearly double the sensitivity in vessels due to the high reflectivity of Epner’s finish.

- Northrup-Grumman: Acknowledging invaluable contributions and essential role in achieving goals.

- TRW Space & Technology Division: Highlighting the incomparable quality of Laser Gold coating.

These testimonials reflect Epner Technology’s reputation for quality and reliability. Read more about customer success stories and industry impact at pioneer-technology.com.

17. What Innovations Can We Expect from Epner Technology in the Future?

In the future, we can anticipate Epner Technology continuing to innovate in electroplating, developing new coatings and processes that meet the evolving needs of high-tech industries. Expect advancements in materials science, enhanced precision, and sustainable plating solutions.

Potential future innovations include:

- Advanced Coatings: Developing new materials with enhanced properties.

- Sustainable Plating: Creating environmentally friendly plating processes.

- Precision Technology: Improving the accuracy and consistency of plating applications.

- Custom Solutions: Tailoring plating solutions for emerging technologies.

Stay ahead of the curve with the latest technological innovations at pioneer-technology.com.

18. How Does Epner Technology Ensure Excellent Communication with Clients?

Epner Technology ensures excellent communication with clients by prioritizing a thorough understanding of their requirements and maintaining open lines of communication throughout the plating process. This approach allows Epner Technology to tailor its services to meet the specific needs of each customer, ensuring satisfaction and optimal results.

Key communication strategies include:

- Detailed Consultations: Understanding customer requirements from the outset.

- Open Dialogue: Maintaining clear and consistent communication.

- Custom Solutions: Tailoring plating processes to meet specific needs.

- Feedback Integration: Incorporating customer feedback for continuous improvement.

Learn more about effective communication in technology and innovation at pioneer-technology.com.

19. What are the Key Benefits of Visiting pioneer-technology.com?

Visiting pioneer-technology.com provides numerous benefits for those interested in advanced materials and technologies. You can access detailed information, expert analyses, and the latest updates on electroplating advancements, as well as explore case studies and innovative solutions that can help solve specific technical challenges.

Key benefits of visiting pioneer-technology.com:

- Comprehensive Information: Access in-depth articles on advanced technologies.

- Expert Insights: Gain knowledge from industry professionals.

- Latest Updates: Stay informed on the newest technological breakthroughs.

- Case Studies: Learn from real-world applications and solutions.

- Innovation Showcase: Discover groundbreaking advancements in various fields.

Unlock the potential of cutting-edge technology by visiting pioneer-technology.com today.

20. Frequently Asked Questions (FAQs) About Epner Technology

Q1: What is Epner Technology known for?

Epner Technology is known for its expertise in high-tech specification electroplating, particularly its proprietary Laser Gold coating used in aerospace, defense, and the arts.

Q2: What is Laser Gold?

Laser Gold is a proprietary, electrochemically deposited gold coating known for its exceptional infrared (IR) reflectivity, ultra-low emissivity, and hardness.

Q3: What industries does Epner Technology serve?

Epner Technology serves a wide range of industries, including aerospace, defense, telecommunications, automotive, and the arts.

Q4: What quality standards does Epner Technology adhere to?

Epner Technology adheres to all applicable ASTM, AMS, MIL, and Prime Contractor specifications and maintains a Quality System that implements ISO 9001:2008.

Q5: How does Epner Technology contribute to space exploration?

Epner Technology provides specialized coatings like Laser Gold for thermal control and reflectivity on spacecraft and satellites, ensuring optimal performance in the harsh conditions of space.

Q6: What are light pipes, and how does Epner Technology enhance them?

Light pipes are tubes lined with a highly polished, infrared-reflective coating. Epner Technology enhances them by lining them with Laser Gold, maximizing light transmission efficiency.

Q7: What is Laser Black, and how is it used?

Laser Black is a velvet-like metallic oxide coating known for its ability to absorb light and prevent out-gassing, used in applications where light absorption and thermal stability are critical.

Q8: What is High-Q Silver, and what are its advantages?

High-Q Silver is an ultra-pure, un-brightened silver coating known for its enhanced crystal structure, providing superior electrical conductivity and reflectivity.

Q9: How does Epner Technology support the arts?

Epner Technology supports the arts by applying its high-tech know-how to create stunning and durable finishes for sculptures, artworks, and jewelry.

Q10: Where can I find more information about Epner Technology?

You can find more information about Epner Technology and its services at pioneer-technology.com, where you can explore detailed articles, expert insights, and the latest technological breakthroughs.

By exploring these FAQs and delving deeper into the resources at pioneer-technology.com, you’ll gain a comprehensive understanding of Epner Technology’s innovative solutions and their impact across various industries.