Ready Technology Inc is a pioneering force in technology, specializing in advanced manufacturing processes to enhance the life and performance of SuperSprings and other critical components, and you can explore more at pioneer-technology.com. By utilizing state-of-the-art equipment and adhering to strict quality standards, Ready Technology Inc ensures unparalleled quality and dependability. Ready Technology Inc delivers high-performance solutions through precision engineering, innovative materials, and rigorous testing, setting new benchmarks in technological excellence.

1. What Makes Ready Technology Inc a Leader in Technology?

Ready Technology Inc stands out as a leader in technology due to its unwavering commitment to innovation, quality, and performance. The company’s dedication to precision engineering and advanced manufacturing processes ensures its products meet the highest standards of reliability and longevity. Ready Technology Inc’s SuperSprings, for instance, are manufactured using vacuum degassed, valve spring quality alloy steel and undergo meticulous inspection to guarantee dimensional accuracy. Ready Technology Inc excels in enhancing product lifespan and performance through heat treating, shot peening, and presetting.

1.1. How Does Ready Technology Inc Ensure High Performance?

Ready Technology Inc ensures high performance through several key processes:

- Optimum Design: Each SuperSpring is engineered with the ideal design, pitch, and metallurgical content for efficient performance.

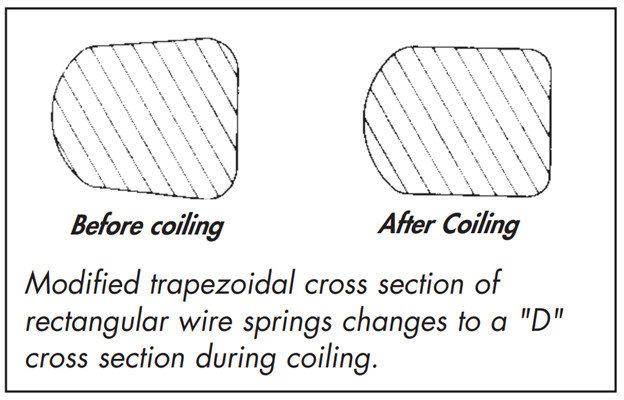

- Advanced Manufacturing: Rectangular wire springs are made from trapezoidal cross-section wire, which transforms into a “D” cross-section during coiling, reducing stress levels and extending spring life.

- Precision Heat Treating: This process enhances the material properties for increased durability.

- Shot Peening: This technique reduces mechanical stresses, further improving fatigue resistance.

- Presetting: Compressing the springs to solid increases set resistance and enhances long-term performance.

1.2. What Materials Does Ready Technology Inc Use?

Ready Technology Inc exclusively uses vacuum degassed, valve spring quality alloy steel to manufacture its SuperSprings. This high-quality material ensures consistent performance and durability, meeting the stringent requirements of demanding applications.

1.3. How Does Ready Technology Inc Maintain Quality Assurance?

Quality assurance at Ready Technology Inc is maintained through rigorous inspection and documentation of each production run. State-of-the-art equipment, including CNC coiling and grinding machines, ensures consistent dimensional accuracy within the narrowest tolerances. This meticulous approach guarantees that every SuperSpring meets the highest quality standards.

2. What Are SuperSprings and Their Key Features?

SuperSprings are high-performance die springs engineered for long service life and dependable performance in demanding applications. Key features include their availability in four color-coded load classifications, guaranteed fit, and full interchangeability. Ready Technology Inc ensures SuperSprings deliver consistent and reliable performance through innovative design and meticulous manufacturing processes.

2.1. What Are the Load Classifications of SuperSprings?

SuperSprings are available in four color-coded load classifications, allowing users to easily identify the appropriate spring for their specific application. These classifications ensure optimal performance and longevity.

- Light Load: Designed for applications requiring minimal force.

- Medium Load: Suitable for general-purpose applications.

- Heavy Load: Ideal for high-force applications.

- Extra Heavy Load: Provides maximum force for the most demanding applications.

2.2. How Does Ready Technology Inc Guarantee the Fit of SuperSprings?

Ready Technology Inc guarantees the fit of SuperSprings by ensuring that spring diameters match the hole and rod diameters listed in the dimensional data. This precise engineering ensures seamless integration into various applications.

2.3. What Standards Do SuperSprings Adhere To?

SuperSprings adhere to ISO 10243 standards, ensuring consistency in lengths, diameters, rates, and colors. This compliance guarantees that SuperSprings meet international quality and performance benchmarks.

3. How Does Ready Technology Inc Enhance Spring Life?

Ready Technology Inc enhances spring life through a combination of advanced manufacturing processes and material selection. Precision heat treating, shot peening, and presetting are critical steps in ensuring SuperSprings offer extended service life and reliable performance. Ready Technology Inc’s meticulous approach to manufacturing ensures that its springs withstand the rigors of demanding applications.

Comparison of cross sections before and after coiling

Comparison of cross sections before and after coiling

3.1. What Role Does Heat Treating Play in Enhancing Spring Life?

Heat treating plays a crucial role in enhancing spring life by improving the material properties of the steel. This process increases the spring’s strength and resistance to deformation, ensuring it can withstand high stresses over extended periods.

3.2. How Does Shot Peening Reduce Mechanical Stresses?

Shot peening reduces mechanical stresses by bombarding the surface of the spring with small shot, creating compressive stress layers. These layers counteract tensile stresses that can lead to fatigue and failure, significantly extending the spring’s lifespan.

3.3. Why Is Presetting Important for Spring Performance?

Presetting is important for spring performance because it involves compressing the spring to its solid height during manufacturing. This process increases the spring’s resistance to permanent set and fatigue, ensuring it maintains its performance characteristics over time.

4. What is the Significance of Vacuum Degassed Alloy Steel in SuperSprings?

The use of vacuum degassed, valve spring quality alloy steel in SuperSprings is significant because it ensures the highest levels of purity and consistency in the material. Vacuum degassing removes impurities that can compromise the steel’s strength and fatigue resistance, resulting in a more durable and reliable spring.

4.1. How Does Vacuum Degassing Improve Steel Quality?

Vacuum degassing improves steel quality by removing dissolved gases, such as hydrogen and nitrogen, and other impurities from the molten steel. This process reduces the risk of inclusions and voids that can weaken the material, resulting in a stronger and more consistent alloy.

4.2. What Are the Benefits of Using Valve Spring Quality Steel?

Valve spring quality steel offers several benefits, including high tensile strength, excellent fatigue resistance, and consistent performance under high-stress conditions. These properties are essential for ensuring the reliability and longevity of SuperSprings in demanding applications.

4.3. How Does Ready Technology Inc Ensure Material Consistency?

Ready Technology Inc ensures material consistency through strict quality control processes, including thorough testing and documentation of each production run. This meticulous approach guarantees that all materials meet the required specifications for optimal performance.

5. How Does Ready Technology Inc Use CNC Coiling and Grinding?

Ready Technology Inc utilizes state-of-the-art CNC coiling and grinding equipment to achieve consistent dimensional accuracy in SuperSprings. These advanced machines ensure that each spring is manufactured to the tightest tolerances, resulting in superior performance and reliability.

5.1. What Is CNC Coiling and Its Advantages?

CNC coiling is a computer-controlled process that precisely forms the spring to the desired shape and dimensions. The advantages of CNC coiling include high accuracy, repeatability, and the ability to produce complex spring designs with consistent quality.

5.2. How Does CNC Grinding Improve Spring Performance?

CNC grinding improves spring performance by ensuring that the ends of the spring are perfectly flat and perpendicular to the spring axis. This precise grinding ensures even load distribution and reduces the risk of stress concentrations, enhancing the spring’s lifespan and performance.

5.3. Why Is Dimensional Accuracy Important in Spring Manufacturing?

Dimensional accuracy is crucial in spring manufacturing because it directly affects the spring’s load characteristics, performance, and reliability. Springs manufactured to precise dimensions ensure consistent and predictable behavior in their intended applications.

6. What Design Factors Influence the Life of SuperSprings?

Several design factors influence the life of SuperSprings, including the ratio of preload to total deflection and the ratio of total deflection to free length. Optimizing these factors can significantly enhance spring life and performance.

6.1. How Does Preload Affect Spring Life?

As the ratio of preload to total deflection increases, spring life also increases. A generous preload in tool design is recommended whenever possible to maximize spring life. Preload helps reduce the stress range experienced by the spring during operation.

6.2. What Is the Impact of Total Deflection on Spring Life?

As the ratio of total deflection to free length decreases, spring life increases. Minimizing the amount of deflection relative to the spring’s free length reduces stress and extends its lifespan.

6.3. How Does Spring Pocket Depth Influence Spring Selection?

Spring life can be improved by drilling the spring pockets deeper and selecting the next longer spring. This approach reduces the amount of deflection required from the spring, thereby decreasing stress and enhancing longevity.

7. How Can Users Select the Right SuperSpring for Their Needs?

Selecting the right SuperSpring for specific needs involves considering factors such as load requirements, desired spring life, and available space. Ready Technology Inc provides charts and tables to assist users in quickly selecting the most suitable die spring.

Spring-Diagram

Spring-Diagram

7.1. What Factors Should Be Considered When Selecting a SuperSpring?

When selecting a SuperSpring, consider the following factors:

- Load Requirements: Determine the maximum force the spring needs to exert.

- Deflection Requirements: Calculate the amount of compression the spring needs to undergo.

- Space Constraints: Ensure the spring fits within the available space.

- Desired Spring Life: Choose a spring that meets the required lifespan for the application.

7.2. How Can Charts and Tables Help in SuperSpring Selection?

Charts and tables provide a quick reference for selecting the appropriate SuperSpring based on specific load and deflection requirements. These resources help users find the optimal spring for their needs, ensuring efficient performance and longevity.

7.3. What Resources Does Ready Technology Inc Provide for Spring Selection?

Ready Technology Inc offers comprehensive resources, including detailed spring tables and selection guides, to assist users in choosing the best SuperSpring for their applications. These resources provide valuable information on spring characteristics and performance.

8. What is Express Ordering and How Does It Benefit Customers?

Express Ordering is a streamlined service that allows customers to quickly view pricing and add items directly to their cart by entering part numbers. This efficient process saves time and simplifies the purchasing experience.

8.1. How Does Express Ordering Work?

Express Ordering works by allowing customers to enter part numbers into a dedicated interface, which then displays pricing and availability. Customers can add items to their cart directly from this interface, streamlining the ordering process.

8.2. What Are the Advantages of Using Express Ordering?

The advantages of using Express Ordering include:

- Time Savings: Quickly find and order the required parts without browsing extensive catalogs.

- Simplified Process: Streamlined interface for easy navigation and order placement.

- Real-Time Information: Access to up-to-date pricing and availability.

8.3. How Can Customers Access Express Ordering?

Customers can access Express Ordering through a dedicated link on the Ready Technology Inc website, providing immediate access to the streamlined ordering process.

9. How Does Ready Technology Inc Ensure Dependable Performance?

Ready Technology Inc ensures dependable performance through rigorous quality control measures, advanced manufacturing processes, and the use of high-quality materials. Each SuperSpring undergoes thorough inspection and testing to guarantee consistent performance and reliability.

9.1. What Quality Control Measures Are in Place?

Ready Technology Inc implements stringent quality control measures, including:

- Material Testing: Ensuring all materials meet required specifications.

- Dimensional Inspection: Verifying that each spring meets precise dimensional tolerances.

- Performance Testing: Evaluating spring performance under various load and stress conditions.

- Documentation: Maintaining detailed records of each production run.

9.2. How Does Ready Technology Inc Test SuperSprings?

Ready Technology Inc tests SuperSprings through a variety of methods, including:

- Load Testing: Measuring the force exerted by the spring at specific deflections.

- Fatigue Testing: Assessing the spring’s ability to withstand repeated stress cycles.

- Dimensional Verification: Ensuring the spring meets precise dimensional requirements.

9.3. Why Is Documentation Important for Ensuring Dependable Performance?

Documentation is crucial for ensuring dependable performance because it provides a record of each production run, allowing for traceability and verification of quality control measures. This documentation helps maintain consistency and identify any potential issues.

10. What Are the Applications of SuperSprings?

SuperSprings are used in a wide range of applications that require high-performance, reliable springs. Common applications include die sets, molds, heavy machinery, and automotive components. Ready Technology Inc’s SuperSprings provide consistent and dependable performance in demanding environments.

10.1. How Are SuperSprings Used in Die Sets and Molds?

In die sets and molds, SuperSprings provide the force needed to precisely form and eject parts. Their high load capacity and long lifespan make them ideal for these demanding applications, ensuring consistent and reliable performance.

10.2. What Role Do SuperSprings Play in Heavy Machinery?

SuperSprings play a critical role in heavy machinery by providing the necessary support and cushioning to absorb shocks and vibrations. Their robust design and dependable performance ensure the machinery operates smoothly and efficiently.

10.3. How Are SuperSprings Utilized in Automotive Components?

In automotive components, SuperSprings are used in various applications, including suspension systems and engine components. Their high-performance characteristics and durability ensure reliable performance and contribute to overall vehicle safety and efficiency.

Ready Technology Inc continues to innovate and provide high-quality solutions for a wide range of technological needs. Explore the future of technology with us at pioneer-technology.com, where you’ll find the latest insights, trends, and breakthroughs in the industry. Stay ahead of the curve and discover how Ready Technology Inc is shaping the world of tomorrow.

Frequently Asked Questions (FAQs)

-

What is Ready Technology Inc?

Ready Technology Inc is a technology company specializing in advanced manufacturing processes to enhance the performance and lifespan of critical components like SuperSprings, ensuring high quality and dependability.

-

What are SuperSprings?

SuperSprings are high-performance die springs engineered for long service life and dependable performance in demanding applications, available in four color-coded load classifications with guaranteed fit.

-

How does Ready Technology Inc ensure high performance of SuperSprings?

Ready Technology Inc ensures high performance through optimum design, advanced manufacturing, precision heat treating, shot peening, and presetting, using vacuum degassed, valve spring quality alloy steel.

-

What materials are used to manufacture SuperSprings?

SuperSprings are manufactured exclusively from vacuum degassed, valve spring quality alloy steel, ensuring consistent performance and durability.

-

How does Ready Technology Inc maintain quality assurance?

Ready Technology Inc maintains quality assurance through rigorous inspection and documentation of each production run, using state-of-the-art equipment like CNC coiling and grinding machines.

-

What design factors influence the life of SuperSprings?

Design factors influencing the life of SuperSprings include the ratio of preload to total deflection, the ratio of total deflection to free length, and spring pocket depth.

-

How can users select the right SuperSpring for their needs?

Users can select the right SuperSpring by considering load requirements, deflection needs, space constraints, and desired spring life, using charts and tables provided by Ready Technology Inc.

-

What is Express Ordering and how does it benefit customers?

Express Ordering is a streamlined service that allows customers to quickly view pricing and add items directly to their cart by entering part numbers, saving time and simplifying the purchasing process.

-

What are the applications of SuperSprings?

SuperSprings are used in die sets, molds, heavy machinery, and automotive components, providing consistent and dependable performance in demanding environments.

-

How can I stay updated with the latest technology trends and innovations from Ready Technology Inc?

Stay updated by visiting pioneer-technology.com for the latest insights, trends, and breakthroughs in the industry, and to discover how Ready Technology Inc is shaping the future of technology.

Are you ready to explore the forefront of technology? Visit pioneer-technology.com now to discover cutting-edge innovations, in-depth analyses, and the latest technological advancements shaping our world. Don’t miss out on the opportunity to stay ahead—explore, learn, and innovate with us today.